Aquaponics is a sustainable farming practice that combines aquaculture and hydroponics. It relies on a balanced ecosystem where fish waste provides the nutrients for plants to grow, and the plants naturally filter and purify the water for the fish. One essential component of any aquaponics system is mechanical filtration.

What is Mechanical Filtration in Aquaponics?

Mechanical filtration is the process of removing solid waste particles from the water in an aquaponics system. It is the first line of defense in maintaining water quality and preventing debris buildup. Mechanical filters physically trap and collect debris such as fish waste, uneaten food, and plant material, ensuring that the water remains clear and free from contamination.

Understanding the Importance of Mechanical Filtration in Aquaponics Systems

Proper mechanical filtration is crucial for the overall health and functionality of aquaponics systems. By removing solid waste particles, mechanical filters prevent the accumulation of organic matter that can lead to water quality issues and compromise the well-being of the fish and plants. Mechanical filtration also plays a vital role in preventing clogs and blockages in other filtration components, such as biological filters.

Additionally, effective mechanical filtration contributes to the aesthetic appeal of the system by creating visually appealing, crystal-clear water. This not only enhances the overall experience but also allows for better observation of the fish and plants, making it easier to detect any signs of illness or nutrient deficiency.

How Does Mechanical Filtration Work in Aquaponics?

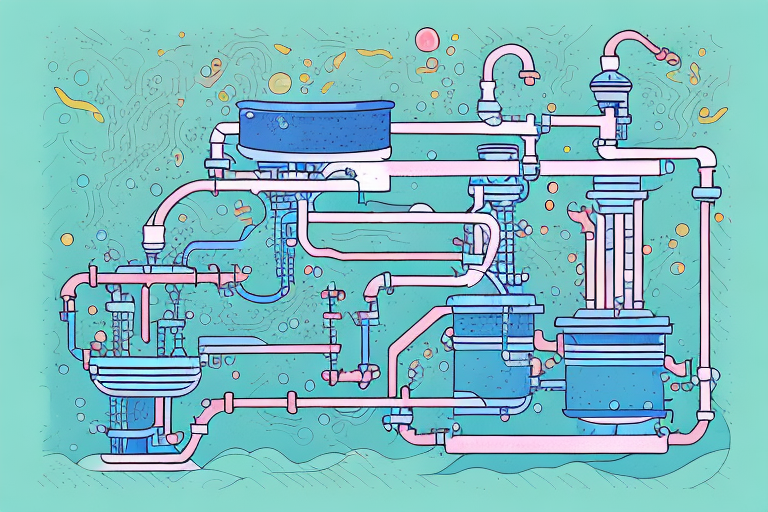

In aquaponics, mechanical filtration typically involves the use of various types of filters to remove solid waste particles from the water. As the water passes through the filter media, the larger particles get trapped, while the clean water continues its journey through the system.

Some mechanical filters utilize physical barriers, such as filter pads or screens, to capture the debris. Others may employ gravity or pressure to force water through a fine mesh or sieve. Each type of mechanical filter has its own unique design and operational characteristics.

Types of Mechanical Filters Used in Aquaponic Systems

There are several types of mechanical filters commonly used in aquaponic systems:

- Filter pads: These are disposable or washable pads made from synthetic materials that efficiently capture solid waste particles. Filter pads are relatively inexpensive and easy to replace or clean.

- Mesh filters: Mesh filters consist of fine screens or sieves that physically trap debris as water passes through them. They can be constructed from various materials, such as nylon or stainless steel, and are available in different mesh sizes to suit specific filtration needs.

- Settling tanks: Also known as sedimentation tanks, settling tanks use gravity to allow the suspended solids in the water to settle at the bottom. The clarified water is then collected and directed back into the system.

- Cyclone filters: Cyclone filters use centrifugal force to separate solids from the water. The swirling motion created inside the filter causes heavier particles to be directed towards the outer wall, where they can be easily removed.

Choosing the Right Mechanical Filter for Your Aquaponics Setup

Choosing the right mechanical filter for your aquaponics setup depends on various factors, such as the size of your system, the stocking density of fish, and the desired level of maintenance. Consider the following:

- Filtration capacity: Ensure that the filter you select can handle the volume of water in your system and effectively remove the anticipated amount of waste.

- Maintenance requirements: Some filters may require more frequent cleaning or replacement of filter media. Assess the time and effort you are willing to invest in maintaining the filter.

- Compatibility: Ensure that the mechanical filter integrates seamlessly with your existing filtration system and does not impede the flow of water or cause backpressure.

- Cost: Consider the initial cost of the filter as well as any ongoing expenses, such as filter pads or mesh replacements.

By carefully considering these factors, you can select a mechanical filter that suits your specific aquaponic needs and ensures optimal performance in your system.

The Role of Mechanical Filtration in Maintaining Water Quality in Aquaponics

Maintaining water quality is of utmost importance in aquaponics. Poor water quality can lead to stressed fish, nutrient imbalances, and increased susceptibility to diseases. By removing solid waste particles, mechanical filtration plays a pivotal role in upholding water quality standards.

As fish produce waste and plants shed dead leaves, these solid particles can accumulate and disrupt the balance of the system. Mechanical filters prevent this buildup, reducing the risk of ammonia spikes, nitrate accumulation, and other unwanted changes in water chemistry.

Moreover, by removing debris, mechanical filtration optimizes the efficiency of subsequent filtration stages, such as biological and chemical filtration, which rely on clear and pristine water to function effectively. Thus, mechanical filtration acts as a protective barrier for the overall well-being of the aquaponic system.

Pros and Cons of Using Mechanical Filtration in Aquaponics Systems

Using mechanical filtration in aquaponics offers numerous benefits, but it is essential to consider the potential drawbacks as well.

Pros:

- Prevents clogs in other filtration components

- Improves water clarity

- Reduces the risk of nutrient imbalances

- Provides physical debris removal

- Promotes healthier fish and plants

Cons:

- Requires regular maintenance

- May increase the cost of operation due to filter replacements or cleaning

- Can restrict water flow if not properly sized or maintained

Understanding the advantages and disadvantages can help you make an informed decision about incorporating mechanical filtration into your aquaponics system.

Tips for Proper Maintenance of Mechanical Filters in Aquaponics

To ensure the longevity and effectiveness of your mechanical filters, it is crucial to perform regular maintenance. Here are a few tips to keep in mind:

- Regular cleaning: Clean or replace filter media as recommended by the manufacturer to prevent clogs and maintain optimal performance.

- Monitor for signs of wear: Inspect the filter housing, seals, and connections regularly for any signs of damage or deterioration. Replace any worn-out parts promptly.

- Adjust filtration rate: Depending on the waste load in your system, you may need to adjust the flow rate through the mechanical filter to ensure efficient filtration. Consult your setup’s documentation for guidance on flow rates.

- Keep spare parts on hand: Always have spare filter pads, mesh screens, or other replaceable parts readily available to avoid interruption in filtration.

By following these maintenance tips, you can keep your mechanical filters running smoothly and prolong their lifespan, ensuring continued effectiveness in your aquaponics system.

Troubleshooting Common Issues with Mechanical Filtration in Aquaponics

Despite regular maintenance, mechanical filtration systems in aquaponics may encounter occasional issues. Here are some common problems and their potential solutions:

- Clogs or reduced flow: Check for any obstructions in the filter media or plumbing. Clean or replace any clogged filter elements and ensure that the filter housing is correctly assembled.

- Water bypassing the filter: Ensure that the mechanical filter is appropriately sized and matched to the flow rate of your system. Check for any loose connections or faulty seals.

- Overflowing settling tanks: If the solids are not settling properly in the tank, consider increasing the settling time or using a different media that allows for better clarification.

If these troubleshooting steps do not resolve the issue, consult the manufacturer’s instructions or seek advice from aquaponics experts to identify and address the problem effectively.

Innovative Advances in Mechanical Filtration Technology for Aquaponics

The field of aquaponics is continually evolving, and so is the technology associated with mechanical filtration. Innovations in this area aim to enhance filtration efficiency, reduce maintenance requirements, and improve overall system performance.

Some recent advancements include:

- Automatic self-cleaning filters: These filters utilize innovative mechanisms, such as rotating brushes or backwashing, to automatically remove accumulated debris without manual intervention.

- In-line particle counters: These devices allow for real-time monitoring of water clarity and the concentration of suspended solids, providing valuable data for better system management.

- Smart filtration systems: Integrated systems that utilize sensors and automation technology to optimize filtration performance based on real-time water quality parameters.

These advancements offer exciting possibilities for aquaponic enthusiasts and professionals alike, promising improved efficiency, reduced labor requirements, and greater control over water quality management.

Case Studies: Successful Implementation of Mechanical Filtration in Aquaponic Farms

Real-world case studies provide valuable insights into the practical application of mechanical filtration in different aquaponic setups. They offer a glimpse into the challenges encountered, solutions implemented, and the positive outcomes achieved.

For example, a commercial aquaponic farm successfully implemented a combination of settling tanks and mesh filters to remove solid waste from the system. By regularly monitoring and adjusting the settling time, they achieved exceptional water clarity and experienced improved fish health and growth rates.

Another case study involved a small-scale home aquaponic system that incorporated a cyclone filter to remove coarse particles before passing the water through additional stages of filtration. This approach reduced the frequency of cleaning and improved the overall efficiency of the filtration system.

Looking into case studies can provide inspiration and practical guidance to aquaponic enthusiasts of all scales, from small backyard setups to large commercial ventures.

Comparing Mechanical Filtration with Other Methods of Water Treatment in Aquaponics

While mechanical filtration is essential in maintaining water quality, it is worth exploring how it compares to other methods of water treatment commonly employed in aquaponics. Understanding the strengths and limitations of each approach allows for informed decision-making.

Biological filtration, for instance, relies on beneficial bacteria to convert toxic ammonia into nitrite and then into nitrate. This process removes harmful substances from the water, contributing to a healthy aquatic environment. Biological filtration is complementary to mechanical filtration, as it addresses different aspects of water quality management.

Chemical filtration, on the other hand, utilizes materials such as activated carbon or zeolite to remove impurities and unwanted substances from the water. Chemical filtration can help in situations where specific water parameters need adjustment or when removing residual chemicals or medications from the system. However, it is important to note that chemical filtration should be used sparingly and only when necessary, as it can potentially disrupt the delicate balance of the aquaponic ecosystem.

Ultimately, a combination of mechanical, biological, and possibly selective chemical filtration is often employed to achieve optimal water quality in aquaponics.

Overcoming Challenges with Mechanical Filtration Systems in Aquaponics

Implementing mechanical filtration in aquaponic systems can present certain challenges. Addressing these challenges is essential for ensuring the smooth operation and efficacy of the filtration system.

One common challenge is maintaining the balance between filtration efficiency and water flow. It is crucial to select the appropriate filter size and type that can effectively remove solid waste while allowing adequate water circulation without excessive backpressure.

Another challenge is the potential for clogs or obstructions in the filter media. Regular cleaning or replacement of the filter pads or screens, as well as implementing periodic flushing or backwashing, can mitigate this issue.

Furthermore, mechanical filtration can lead to the generation of excess organic matter, such as sludge or mulm, which can accumulate in settling tanks or on the filter media. Monitoring and adjusting the settling time, as well as incorporating biological filtration components, can help manage this organic buildup.

By identifying and proactively addressing these challenges, aquaponic enthusiasts can maximize the effectiveness of their mechanical filtration systems and maintain optimal water quality for the success of their aquatic and plant life.

Best Practices for Optimizing Efficiency and Performance of Mechanical Filters in Aquaponic Systems

To achieve optimal efficiency and performance of mechanical filters in aquaponic systems, consider implementing the following best practices:

- Balanced stocking density: Avoid overcrowding your system with too many fish for the filtration capacity to handle. Maintaining a balanced stocking density ensures that the mechanical filter can adequately process the waste produced.

- Regular monitoring: Keep a close eye on water clarity, flow rates, and any deviations from the norm. Timely detection allows for swift action to correct any issues.

- Establish maintenance routines: Develop a regular maintenance schedule for cleaning or replacing filter media. This includes staying on top of sludge or mulm buildup in settling tanks if applicable.

- Consider redundancy: Incorporate backup mechanical filters or redundancy systems to avoid system failures in case of filter malfunctions or unexpected issues.

- Continuous improvement: Stay informed about the latest advancements in mechanical filtration technology and explore opportunities for upgrading or fine-tuning your system for enhanced performance.

By following these best practices, aquaponic enthusiasts can ensure that their mechanical filtration systems operate at peak efficiency, supporting the overall health and productivity of the aquaponic ecosystem.

As the backbone of water quality management in aquaponics systems, mechanical filtration is an essential component for maintaining the delicate balance between fish and plant health. Through effective removal of solid waste particles, mechanical filters safeguard the system from potential harm and support the optimal functioning of other filtration stages. By harnessing the power of mechanical filtration and incorporating best practices, aquaponic enthusiasts can create thriving ecosystems that provide a sustainable and bountiful harvest.