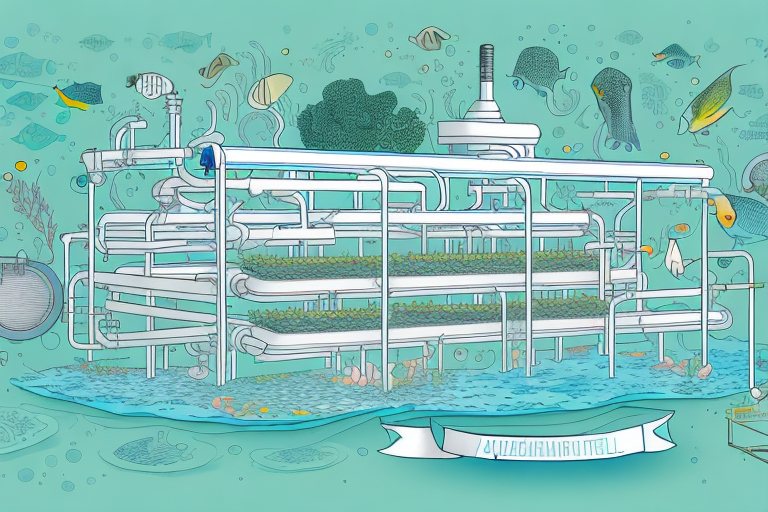

Aquaponics is an innovative system that combines aquaculture (the cultivation of aquatic animals) with hydroponics (the cultivation of plants in water). This symbiotic relationship between fish and plants creates a sustainable and highly efficient method of food production. As the demand for environmentally friendly and resource-efficient agriculture practices grows, the role of industrialization in scaling up aquaponics becomes crucial.

Understanding the Basics of Aquaponics

Aquaponics operates on the principle that fish excrete ammonia, which is converted into nitrates by naturally occurring bacteria in the system. These nitrates serve as the primary source of nutrients for the plants, while the plants filter the water, removing the excess nitrates and providing clean water for the fish.

By mimicking the natural nitrogen cycle, aquaponics eliminates the need for synthetic fertilizers and minimizes water usage. This closed-loop system maximizes resource efficiency, making it an attractive option for sustainable agricultural practices.

In addition to its resource efficiency, aquaponics also offers several other benefits. One of the key advantages is its ability to produce both fish and plants simultaneously. This dual production system allows for a diverse range of food options, providing a sustainable source of protein and fresh produce.

Furthermore, aquaponics can be implemented in various settings, including urban environments. Its compact design and vertical farming techniques make it suitable for small spaces, such as rooftops or indoor facilities. This accessibility allows for local food production, reducing the need for long-distance transportation and minimizing carbon emissions.

Exploring the Potential of Aquaponics for Sustainable Agriculture

Aquaponics offers numerous benefits for sustainable agriculture. Firstly, it significantly reduces water consumption compared to traditional farming methods. The recirculating water system eliminates the need for constant water replenishment, resulting in up to 90% less water usage.

Secondly, aquaponics minimizes the use of synthetic fertilizers. The natural conversion of fish waste into plant nutrients creates a self-sustaining ecosystem that does not require the addition of chemical fertilizers, reducing harmful runoff into water bodies and avoiding soil degradation.

Furthermore, aquaponics does not require large tracts of land, making it suitable for urban and peri-urban areas. By utilizing vertical farming techniques and compact system designs, aquaponics can be implemented in small spaces, maximizing food production in areas with limited arable land.

Another advantage of aquaponics is its ability to produce both fish and plants simultaneously. In traditional farming, separate systems are required for fish farming and plant cultivation. However, in aquaponics, the fish waste provides essential nutrients for the plants, while the plants filter and purify the water for the fish. This symbiotic relationship allows for efficient use of resources and increased productivity.

In addition, aquaponics systems can be easily customized and scaled to meet specific needs. Whether it’s a small-scale system for personal use or a large commercial operation, aquaponics can be adapted to fit different spaces and production goals. This flexibility makes it a viable option for a wide range of farmers, from hobbyists to entrepreneurs.

The Impact of Industrialization on Aquaponics Systems

Industrialization plays a vital role in scaling up aquaponics systems to meet the increasing demand for sustainable food production. The integration of industrial practices helps enhance efficiency, productivity, and profitability of aquaponic farms.

One of the main impacts of industrialization is the automation of various processes within the aquaponics system. Automated feeding systems, water quality monitoring, and plant nutrient management systems streamline operations and reduce labor requirements. This not only increases productivity but also reduces the likelihood of human error and ensures consistent and optimal conditions for plant and fish growth.

Furthermore, industrialization in aquaponics systems has led to the development of advanced technologies that improve resource utilization and environmental sustainability. For example, the use of energy-efficient LED lighting systems allows for precise control over light intensity and spectrum, optimizing plant growth while minimizing energy consumption. Additionally, the integration of renewable energy sources such as solar panels and wind turbines helps reduce reliance on traditional energy grids and lowers the carbon footprint of aquaponic farms.

How Industrialization Can Enhance Efficiency in Aquaponics

Industrialization brings advancements in technology, which can significantly enhance the efficiency of aquaponics systems. The integration of advanced sensors and controls enables real-time monitoring and adjustments of water parameters, such as temperature, pH levels, and dissolved oxygen. By maintaining optimal conditions, industrialized aquaponics systems can achieve higher crop yields and faster fish growth rates.

Additionally, the use of energy-efficient components, such as LED lighting for plant growth, reduces energy consumption in aquaponics farms. Energy-efficient systems not only contribute to sustainability but also lower operational costs, making aquaponics a financially viable option for large-scale production.

Furthermore, industrialization in aquaponics allows for the automation of various tasks, reducing the need for manual labor. Automated systems can handle tasks such as feeding the fish, monitoring water quality, and harvesting crops. This not only increases efficiency but also frees up labor resources to focus on other important aspects of the aquaponics operation, such as system maintenance and crop management.

Innovations in Industrial Aquaponics Technology

The continuous advancements in industrial aquaponics technology are driving the scalability and profitability of these systems. Vertical farming techniques, where plants are arranged in stacked layers, maximize space utilization, allowing for higher production volumes in smaller footprints.

In addition to vertical farming, integrated aquaponics systems that combine fish farming with other forms of agriculture, such as hydroponics or vermiculture, are gaining popularity. These integrated approaches maximize resource utilization and diversify revenue streams, enhancing the economic viability of aquaponics operations.

Another innovation in industrial aquaponics technology is the use of advanced monitoring and control systems. These systems utilize sensors and automation to continuously monitor and adjust key parameters such as water quality, temperature, and nutrient levels. This real-time data allows for precise control and optimization of the aquaponics system, resulting in improved efficiency and productivity.

Scaling up Aquaponics: Benefits and Challenges

Scaling up aquaponics offers several benefits, including increased food production, improved economic viability, and greater market impact. By expanding the scale of aquaponics systems, it becomes possible to meet the rising demand for sustainable, locally grown produce.

However, scaling up aquaponics also comes with challenges. One major challenge is the need for significant investment in infrastructure, automation, and research and development. Large-scale aquaponics operations require specialized equipment, automated monitoring systems, and robust water filtration systems to maintain the delicate balance between fish and plants.

Moreover, the integration of industrialized aquaponics into existing agricultural supply chains presents logistical challenges. Efficient distribution networks need to be established to ensure timely delivery of fresh produce to consumers, especially in urban areas where demand is highest.

Another challenge in scaling up aquaponics is the need for skilled labor. As the size of aquaponics systems increases, more workers are required to manage and maintain the operations. These workers need to have a deep understanding of aquaponics principles, as well as knowledge in areas such as fish health, plant cultivation, and water chemistry. Training programs and educational initiatives are necessary to develop a skilled workforce that can support the growth of large-scale aquaponics.

Industrialization and the Evolution of Large-Scale Aquaponic Farms

As industrialization progresses, large-scale aquaponic farms are evolving to meet the demands of the market. These farms employ state-of-the-art technologies and methodologies to optimize productivity and achieve commercial success.

Large-scale aquaponic farms often incorporate advanced water filtration systems to ensure water quality and minimize the risk of disease outbreaks. In addition, the development of specialized aquaponics fish breeds and plant varieties enhances growth rates and crop yields, further improving profitability.

The Role of Automation in Industrial Aquaponics Systems

Automation plays a pivotal role in industrial aquaponics systems, streamlining processes and reducing labor requirements. Automated fish feeders accurately dispense feed at regular intervals, ensuring the fish receive the necessary nutrients without wastage.

Furthermore, automated monitoring systems continuously measure critical parameters such as water temperature, pH levels, and dissolved oxygen. Any deviations from optimal conditions can trigger alerts, enabling prompt intervention and preventing potential losses.

Sustainable Practices in Industrial Aquaponics Production

Industrialization in aquaponics must prioritize sustainability by implementing environmentally friendly practices. Proper waste management ensures efficient utilization of fish waste as fertilizer and minimizes the release of pollutants into the environment.

Moreover, employing renewable energy sources, such as solar panels, reduces the carbon footprint of these systems. Implementing energy-efficient components and optimizing electrical consumption further contributes to the overall sustainability of industrial aquaponics production.

Maximizing Crop Yield through Industrial Aquaponics Techniques

Industrialization in aquaponics enables the implementation of advanced techniques to maximize crop yield. These techniques include optimizing plant spacing, fine-tuning nutrient levels, and controlling lighting conditions.

By tailoring the environment to specific crop requirements, industrial aquaponics can achieve faster growth rates, higher yields, and increased crop diversity. This allows for a more efficient use of resources and a greater variety of commercially viable crops.

The Economics of Scaling up Aquaponics Operations

Scaling up aquaponics operations requires a thorough consideration of the economic feasibility. While initial investments may be substantial, the long-term benefits can be significant.

The integration of industrial practices can contribute to cost reduction through energy efficiency, automation, and improved resource management. Additionally, the high demand for sustainably grown produce can create a niche market for aquaponics, allowing for premium pricing and market differentiation.

Case Studies: Successful Integration of Industrialization in Aquaponic Farms

There are several successful case studies showcasing the integration of industrialization in aquaponic farms. These farms have proven the ability to achieve high levels of productivity, profitability, and sustainability.

For example, a large-scale aquaponics farm in the Netherlands utilizes advanced automation systems combined with renewable energy sources, resulting in efficient production and reduced environmental impact. Similarly, a commercial aquaponics operation in Singapore implements vertical farming techniques and precise environmental controls, maximizing land utilization and meeting the city-state’s demand for locally grown produce.

Environmental Impacts of Industrialized Aquaponics Systems

While industrialized aquaponics systems offer many environmental benefits, it is crucial to consider potential impacts on natural ecosystems. Proper management and containment of water effluents are essential to prevent the introduction of non-native species or excess nutrients into surrounding water bodies.

Furthermore, regular monitoring and stringent biosecurity protocols are necessary to mitigate the risk of disease outbreaks and maintain the overall health of the aquaponics system. By implementing environmentally responsible practices, industrialized aquaponics can minimize ecological risks and contribute to sustainable food production.

Overcoming Barriers to Scaling up Aquaponic Operations with Industrialization

Scaling up aquaponic operations with industrialization is not without challenges. Adequate funding, technical expertise, and regulatory support are all crucial factors in overcoming these barriers.

Partnerships between aquaponics entrepreneurs, research institutions, and government agencies can provide the necessary resources and expertise to address these challenges. Knowledge exchange, funding programs, and streamlined regulations can facilitate the expansion and success of industrialized aquaponics operations, ultimately contributing to a more sustainable and resilient food system.

In conclusion, industrialization plays a pivotal role in scaling up aquaponics and maximizing its potential for sustainable food production. Through automation, innovation, and resource optimization, industrialized aquaponic farms can meet the increasing demand for locally grown, environmentally friendly produce. However, ensuring sustainability, minimizing environmental impacts, and overcoming challenges require a collaborative effort from stakeholders across the industry. By embracing industrialization, aquaponics has the potential to revolutionize the future of agriculture and contribute to a more sustainable world.