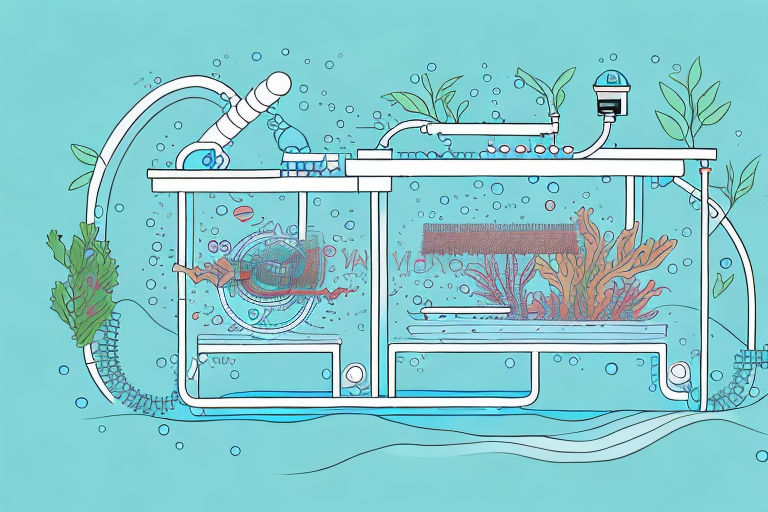

Aquaponics is a rapidly evolving method of agricultural production that combines aquaculture (fish farming) with hydroponics (growing plants in water). This innovative system utilizes the symbiotic relationship between fish and plants to create a sustainable and highly productive farming method. In recent years, aquaponic farms have seen a significant transformation due to the advent of industrialization and automation. These technological advancements have revolutionized the way aquaponics is practiced, resulting in increased efficiency, productivity, and sustainability.

Understanding the Role of Industrialization in Aquaponics

Industrialization in aquaponics involves the scaling up of operations to meet the growing demand for sustainable food production. It encompasses the integration of modern infrastructure, equipment, and processes to maximize output while minimizing resource consumption. Industrialized aquaponic systems often employ large-scale commercial setups that can produce significant quantities of fish and vegetables. By leveraging economies of scale, industrialization allows for the optimization of resources, lower production costs, and increased profitability.

Furthermore, industrialization in aquaponics enables better control and management of crucial environmental factors. Automated systems monitor and regulate variables such as temperature, pH levels, nutrient concentration, and oxygenation, ensuring optimal conditions for both the fish and plants. This level of precision enhances the overall health and growth rate of the system, resulting in higher yields.

The Impact of Automation on Aquaponics Systems

Automation plays a pivotal role in reshaping aquaponic farming practices. It involves the use of advanced technology and robotics to streamline various processes, reducing the need for manual labor and human intervention. Automation offers benefits such as increased efficiency, improved productivity, and enhanced data collection and analysis.

Automated feeding systems, for instance, accurately dispense the precise amount of feed required by the fish, ensuring optimal growth and minimal waste. Similarly, automated harvesting systems facilitate efficient and timely collection of mature crops, minimizing labor requirements and maximizing productivity. These systems can be programmed to harvest specific plant varieties at their peak ripeness, resulting in higher quality produce.

Exploring the Benefits of Industrialized Aquaponics

Industrialized aquaponics offers numerous benefits over traditional farming methods. One significant advantage is the efficient use of resources. The closed-loop nature of aquaponic systems allows for the recycling and reuse of water, significantly reducing water consumption compared to conventional agriculture. Additionally, the integration of aquaculture with hydroponics maximizes nutrient utilization, minimizing the need for synthetic fertilizers. This sustainable approach minimizes waste and environmental impact.

Moreover, industrialized aquaponics offers increased food security and local food production. By cultivating a diverse range of fish and vegetables in controlled environments, aquaponic farms can produce fresh and nutritious food year-round, regardless of seasonal limitations. This localized production ensures a shorter supply chain, reducing transportation costs and emissions associated with long-distance food distribution.

Automation in Aquaponics: Revolutionizing the Way We Grow Food

Automation is revolutionizing the way aquaponics is practiced and shaping the future of food production. As technology continues to advance, robotic systems can perform tasks traditionally done by humans, such as planting, transplanting, and monitoring plant growth. These advancements not only increase operational efficiency but also reduce the physical strain on farmers, enabling them to focus on strategic decision-making and system optimization.

Furthermore, automation enables precise data collection and analysis, facilitating continuous improvement and innovation in aquaponics. Sensors and monitoring devices can capture real-time information about water quality, nutrient levels, and plant health. This data can then be analyzed to detect trends, identify optimization opportunities, and predict potential issues. Automated systems can also alert farmers to any deviations in the system parameters, allowing for proactive intervention and ensuring the well-being of the fish and plants.

Industrialization and Automation: Driving Efficiency in Aquaponics

The combination of industrialization and automation has resulted in a paradigm shift in the aquaponics industry. The integration of advanced technology, streamlined processes, and efficient resource utilization has led to increased productivity and reduced costs. The economies of scale achieved through industrialization allow for substantial production outputs that can meet the demands of large markets.

Moreover, the precision and control offered by automation enable farmers to optimize their operations, ensuring the highest possible yield and quality. By continuously monitoring and adjusting system parameters, aquaponic farms can respond promptly to any changes or challenges, preventing potential losses and maintaining optimal productivity.

The Evolution of Aquaponics through Industrialization and Automation

As aquaponics continues to evolve, industrialization and automation will play increasingly vital roles in shaping the future of sustainable agriculture. The utilization of advanced technologies, such as artificial intelligence and machine learning, holds immense potential for further optimization and innovation in aquaponics.

Moreover, the integration of aquaponics with other emerging technologies, such as vertical farming and renewable energy sources, can lead to even greater efficiency and sustainability. The synergistic combination of these advancements has the potential to establish aquaponic systems as a mainstream method of food production, capable of meeting the global demand for nutritious and environmentally friendly agriculture.

Harnessing Technology to Enhance Aquaponic Production

Aquaponics, with its unique combination of aquaculture and hydroponics, offers a sustainable and resource-efficient farming method. However, harnessing the full potential of aquaponics requires the integration of industrialization and automation. By embracing modern infrastructure, equipment, and processes, aquaponic farms can maximize their efficiency, productivity, and sustainability.

The continuous development and implementation of cutting-edge technologies will drive the future growth of aquaponics. Advanced sensors, robotics, and analytical tools will enable farmers to achieve greater precision and control over their systems, leading to higher yields and improved overall performance. Additionally, the adoption of renewable energy sources and vertical farming techniques will further enhance the sustainability and scalability of aquaponics.

Balancing Tradition with Innovation: The Rise of Industrialized Aquaponics

While industrialization and automation have significant benefits for aquaponics, it is crucial to strike a balance between tradition and innovation. Incorporating traditional farming practices and knowledge into industrialized aquaponic systems can enhance resilience and foster a deeper understanding of the ecological connections within the system.

For example, incorporating polyculture, a traditional farming practice that involves cultivating multiple fish species together, can enhance the ecological balance within the aquaponic system. Similarly, incorporating organic and regenerative farming principles can further promote sustainability and minimize the environmental footprint of aquaponic farms.

How Industrialization and Automation are Transforming Sustainable Agriculture

The integration of industrialization and automation in aquaponics is transforming sustainable agriculture by providing a viable solution to the challenges faced by traditional farming methods. By minimizing resource consumption, optimizing productivity, and reducing environmental impact, industrialized aquaponics offers a blueprint for a more sustainable and resilient food system.

Furthermore, the scalability and controlled environment of aquaponic farms make them suitable for both urban and rural settings. These systems can be established in any location, ranging from small-scale rooftop gardens in urban areas to large-scale commercial operations in rural settings. This versatility allows for a decentralized and localized approach to food production, improving access to fresh and nutritious food while reducing transportation costs and food waste.

Exploring the Future of Aquaponics: The Role of Industrialization and Automation

The future of aquaponics holds immense promise, driven by the ongoing advancements in industrialization and automation. As technology continues to progress, we can expect to see even greater integration of smart systems, robotics, and artificial intelligence in aquaponics.

Vertical farming, with its potential for higher crop densities in limited spaces, is likely to become more prevalent in industrialized aquaponics. These vertically integrated systems will further optimize resource utilization and maximize productivity, paving the way for sustainable and efficient food production in urban areas. Additionally, the development of predictive analytics and advanced control systems will enable farmers to optimize their operations and make data-driven decisions.

Leveraging Technology for Increased Productivity in Aquaponic Systems

As the aquaponics industry continues to grow, technology will play a crucial role in driving increased productivity. The integration of automation and robotics will streamline labor-intensive tasks, allowing farmers to focus on strategic planning and optimization. By automating processes such as seedling transplantation and pest control, aquaponic farms can increase efficiency and reduce costs.

Furthermore, the use of advanced monitoring systems and data analytics will optimize resource allocation and improve overall system performance. Real-time data on water quality, nutrient levels, and plant health can provide valuable insights for system optimization and potential issue prevention. These advancements will enable aquaponic farmers to leverage technology effectively and achieve higher productivity and profitability.

Overcoming Challenges: Adapting Aquaponics to Industrialized and Automated Processes

While industrialization and automation offer numerous benefits to aquaponics, there are also challenges that need to be addressed. Adapting traditional aquaponic practices and knowledge to industrialized and automated processes requires careful consideration and experimentation.

One challenge is the potential for overreliance on technology and the risk of system failures. It is crucial to maintain a balance between automation and manual intervention to ensure the resilience of the system. Regular monitoring, backup systems, and trained personnel can help mitigate risks and ensure the continuity of operations.

Another challenge is the cost of implementing advanced technology and infrastructure. While industrialization and automation have the potential to enhance efficiency and profitability, the initial investment can be significant. However, as the aquaponics industry continues to grow and technology becomes more accessible, the costs are expected to decrease, making these advancements more financially viable for farmers.

Innovations in Aquaponic Design: Integrating Industrialization and Automation

The integration of industrialization and automation in aquaponics is driving innovations in system design. The focus is on developing modular and scalable designs that can be easily replicated and adapted to various settings and requirements. Modular systems allow for flexibility and customization, enabling farmers to scale their operations based on demand.

Additionally, the integration of automation within the physical design of aquaponic systems is being explored. This includes the incorporation of robotics, conveyor belts, and smart sensors directly into the infrastructure. These innovations streamline the movement of fish and plants, optimize feeding and harvesting processes, and provide real-time data for better system management.

Sustainability at Scale: The Prospects of Industrialized and Automated Aquaponics

Industrialized and automated aquaponics hold immense promise in achieving sustainability at scale. By combining aquaculture and hydroponics in controlled environments, these systems provide a resource-efficient and environmentally friendly method of food production.

As the global population continues to grow, the demand for sustainable and nutritious food will only increase. Industrialized and automated aquaponics offer a solution to the challenges faced by traditional agriculture, providing a reliable and resilient method of food production. By leveraging technology, optimizing resource utilization, and focusing on sustainable practices, aquaponics has the potential to play an integral role in ensuring food security and preserving the health of our planet.

In conclusion, industrialization and automation are reshaping the field of aquaponics, enabling scalable, efficient, and sustainable food production. By embracing advanced technology and innovative farming practices, aquaponic farms can significantly increase productivity, minimize resource consumption, and reduce environmental impact. The integration of industrialization and automation in aquaponics holds immense potential for the future of sustainable agriculture, ensuring food security and environmental sustainability for generations to come.