Aquaponics, a sustainable farming method that combines aquaculture and hydroponics, has gained popularity in recent years. By harnessing the natural symbiotic relationship between fish and plants, aquaponics allows farmers to produce both fish and vegetables in a closed-loop system. While this method offers numerous benefits, such as efficient resource utilization and reduced water consumption, the manual labor involved in maintaining such systems can be time-consuming and labor-intensive. This is where automation comes into play.

Introduction to Aquaponics: A Sustainable Farming Method

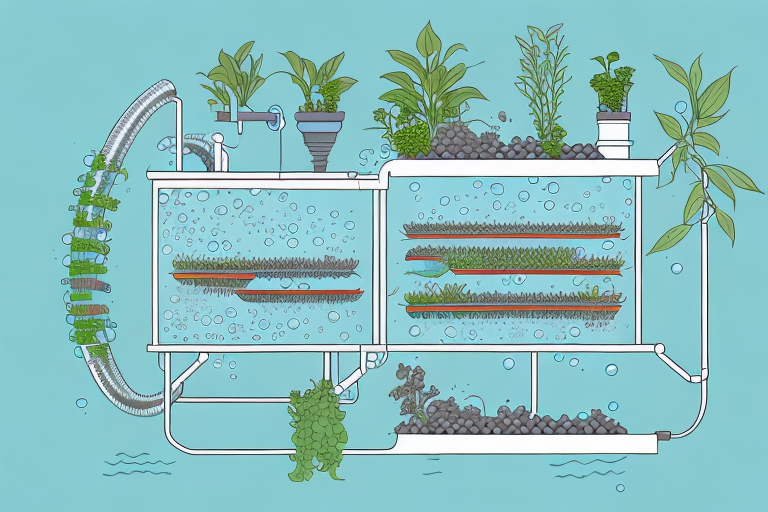

Before diving into the world of automation in aquaponics, it is important to understand the fundamentals of this sustainable farming method. Aquaponics combines aquaculture, which is the farming of fish, with hydroponics, which is the cultivation of plants in water. In a typical aquaponic system, fish waste provides nutrients for the plants, while the plants filter and purify the water for the fish. This symbiotic relationship creates a self-sustaining ecosystem that is environmentally beneficial.

Aquaponics offers several advantages over traditional farming methods. It requires significantly less water, as the water is continuously recycled within the system. Additionally, the absence of soil eliminates the need for pesticides and herbicides, making aquaponics a much safer and more sustainable option. By adopting automation in aquaponics, farmers can further enhance these benefits and optimize their operations.

Exploring the Benefits of Automation in Aquaponics

Automation in aquaponics brings numerous advantages to farmers. Firstly, it greatly reduces the need for manual labor, allowing farmers to focus on other important aspects of their operations. With automated systems taking care of routine maintenance tasks, farmers can spend more time monitoring the health of their fish and plants, as well as developing strategies for improving overall production.

Furthermore, automation contributes to greater efficiency in resource utilization. Automatically controlled systems ensure that fish are fed at the right time and in the correct quantities, minimizing waste and optimizing growth rates. Automated monitoring and control systems also help maintain optimal water parameters, such as temperature, pH levels, and oxygen levels, creating an ideal environment for the fish and plants to thrive.

In addition to improving efficiency, automation enhances productivity in aquaponics. With automated systems taking care of time-consuming tasks like feeding and monitoring, farmers can increase the scale of their operations without a proportional increase in labor requirements. This scalability allows for greater production and potential for higher profits.

The Role of Technology in Modern Aquaponic Systems

Modern aquaponic systems rely heavily on technology to harness the full potential of automation. Various sensors, controllers, and monitoring devices play a crucial role in ensuring the smooth operation of an automated aquaponics farm.

Sensors are used to measure important parameters such as temperature, pH levels, and water flow rates. These sensors provide real-time data that can be used to make informed decisions and adjustments to the system. For example, if the temperature rises above the optimal range for fish, the sensor can trigger an action to activate cooling systems and maintain the ideal conditions.

Controllers, on the other hand, are responsible for receiving data from sensors and initiating the necessary actions. They can be programmed to regulate feeding, adjust temperature and lighting, monitor water levels, and control the flow of water between different system components. Controllers serve as the brain of automated aquaponic systems, ensuring that the right actions are taken at the right time.

Monitoring devices, such as digital displays and remote access systems, allow farmers to keep tabs on their aquaponic systems even when they are not physically present. This remote monitoring capability provides peace of mind and enables timely intervention in case of any system irregularities.

Understanding the Basics of Aquaponic Automation

Aquaponic automation involves the implementation of various technologies to streamline and optimize the operation of the system. To adopt automation in aquaponics, farmers need to understand the basic components and processes involved.

The first step in aquaponic automation is to identify the specific tasks that can be automated. This may include feeding the fish, adjusting water parameters, controlling lighting, managing water flow, and monitoring system performance. By automating these tasks, farmers can reduce manual labor and ensure consistent, precise execution.

Next, farmers need to select the appropriate technologies for their specific needs. This involves researching and understanding the various automation options available in the market. Factors such as system size, budget, and desired level of automation should be taken into consideration when making these decisions.

Once the technologies are chosen, it is crucial to design the system in a way that allows for seamless integration. This may involve installing sensors and controllers at strategic locations, setting up dedicated automation hubs or control panels, and configuring the various components to communicate with each other effectively.

Testing and calibration are vital steps in aquaponic automation. Farmers should ensure that all sensors and controllers are properly calibrated and accurately measure the desired parameters. Regular maintenance and calibration checks should be carried out to keep the system functioning optimally.

Key Components of an Automated Aquaponics System

An automated aquaponics system comprises several key components that work together to create a fully automated and efficient farming environment. These components include:

- Sensors: Temperature, pH, and flow sensors are used to monitor and maintain optimal conditions within the system.

- Controllers: These devices receive data from sensors and trigger appropriate actions, such as adjusting feeding schedules or activating water pumps.

- Feeding Systems: Automated feeding systems dispense the correct amount of fish feed at regular intervals, ensuring optimal growth and minimizing waste.

- Monitoring and Control Systems: These systems provide real-time data on water parameters and enable farmers to control various aspects of the system remotely.

- Irrigation and Filtration Systems: Automated irrigation systems ensure plants receive the right amount of water, while filtration systems help maintain water quality by removing solids and excess nutrients.

- Harvesting Systems: Automated harvesting techniques, such as conveyor belts or robotic arms, can be implemented to streamline the process and optimize yield.

These components, when integrated and properly configured, work together to automate various aspects of aquaponic farming, freeing up time and resources for farmers to focus on other important activities.

Selecting the Right Automation Technologies for Your Aquaponic Farm

The process of selecting the right automation technologies for an aquaponic farm can seem overwhelming at first. However, by considering various factors and conducting thorough research, farmers can make informed decisions that best suit their specific needs and goals.

The first consideration is the size and scale of the farm. Smaller farms with fewer fish tanks and plant beds may require less complex automation systems. On the other hand, larger farms with numerous tanks and beds will require more advanced technologies to ensure seamless integration and effective management.

Budget is another crucial factor when selecting automation technologies. Farmers should have a clear understanding of their financial constraints and allocate funds accordingly. It is important to strike a balance between the desired level of automation and the resources available.

Compatibility with existing systems should also be taken into account. In many cases, farmers may already have some level of automation in place. When selecting new technologies, it is important to ensure compatibility and integratability with the existing infrastructure.

Finally, farmers should consider the level of technical expertise available on their farm. Some automation technologies may require extensive programming or technical knowledge to install and maintain. It is important to assess the capabilities of the farm’s personnel and select technologies that align with their skillset.

By considering these factors and thoroughly researching various automation technologies available in the market, farmers can make informed decisions and select the right tools to enhance automation in their aquaponic farms.

Enhancing Efficiency and Productivity with Automated Monitoring and Control Systems

Automated monitoring and control systems play a crucial role in enhancing efficiency and productivity in aquaponics. These systems enable farmers to continuously monitor important parameters and make adjustments as needed, without the need for manual intervention.

Temperature and pH sensors are key components of monitoring systems. By continuously monitoring these parameters, farmers can ensure that the fish and plants are kept in their ideal conditions. Deviations from the optimal ranges can trigger alerts, allowing farmers to take corrective actions promptly.

Water level sensors are also critical in an automated aquaponics system. They help maintain the desired water level in fish tanks and plant beds, ensuring proper water circulation and preventing flooding or drying out of the beds.

Moreover, automated monitoring and control systems enable precise management of water flow. By controlling the flow rates between the fish tanks, filtration systems, and plant beds, farmers can ensure optimal nutrient delivery to the plants and efficient removal of fish waste.

Lighting control is another important aspect of automated monitoring systems. By adjusting the duration and intensity of light exposure, farmers can optimize plant growth and flowering, resulting in higher yields.

Remote access capabilities, provided by monitoring and control systems, allow farmers to monitor their aquaponic systems from anywhere. This real-time access to data and control functionality not only increases convenience but also enables prompt response to any issues that may arise.

Overall, automated monitoring and control systems contribute to greater efficiency and productivity by providing real-time data, allowing for prompt intervention, and ensuring optimal conditions for fish and plants in an aquaponic system.

Streamlining Water Management with Automated Irrigation and Filtration Systems

Water management is a crucial aspect of aquaponic farming. Ensuring proper irrigation and filtration are essential for maintaining water quality, nutrient balance, and overall system health. Automation can greatly streamline these processes and optimize water management in an aquaponic system.

Automated irrigation systems ensure that plants receive the right amount of water at the right time. By accurately measuring water levels and utilizing timers or moisture sensors, these systems deliver water precisely and minimize waste. In addition, automated irrigation systems can be programmed to provide different watering schedules and durations, allowing for optimal growth conditions for different types of plants.

Filtration systems play a vital role in maintaining water quality in an aquaponic system. Automated filtration systems remove excess nutrients, fish waste, and solid particles from the water, ensuring a clean and balanced environment for fish and plants. Monitoring sensors can be integrated into these systems to measure water quality parameters, such as ammonia levels and dissolved oxygen, allowing for timely adjustments and maintenance.

Automated water level sensors serve as an essential component of water management in aquaponics. These sensors continuously monitor water levels in fish tanks and plant beds, ensuring that the system maintains the appropriate water circulation and prevents any water-related issues.

By automating irrigation and filtration processes, farmers can optimize water usage, maintain water quality, and create a more efficient and sustainable aquaponic system.

Automating Feeding Processes for Optimal Fish and Plant Growth

Feeding the fish in an aquaponic system at the right time and in the correct quantities is crucial for their growth and overall health. Automation can play a significant role in ensuring that fish are fed optimally, minimizing waste and maximizing growth rates.

Automated fish feeding systems are designed to dispense the correct amount of feed at regular intervals. These systems can be programmed to provide multiple feeding sessions throughout the day, simulating the natural feeding patterns of the fish. By automating the feeding process, farmers eliminate the need for manual feeding and reduce the chances of overfeeding, which can lead to water pollution and fish health issues.

Feeding systems can also be integrated with monitoring and control systems to ensure precise feeding quantities and adjust feeding schedules based on fish behavior and growth rates. Real-time data from sensors, such as water quality or fish weight, can be used to fine-tune feeding parameters and optimize the nutritional needs of the fish.

Furthermore, automated feeding systems can be coupled with waste removal mechanisms to collect and remove uneaten feed or fish waste from the system. This prevents water contamination and maintains a clean and healthy environment for the fish and plants.

By automating the feeding process, farmers can ensure that fish receive the right amount of feed at the right time, promoting optimal growth, reducing waste, and maintaining a healthy ecosystem within the aquaponic system.

Maximizing Yield and Minimizing Waste through Automated Harvesting Techniques

Harvesting is a critical aspect of aquaponic farming, as it determines the yield and quality of both fish and plants. Automation can greatly optimize the harvesting process, maximizing yield and minimizing waste.

Automated harvesting techniques can be implemented to streamline the collection and processing of fish and plants. For fish, automated systems like conveyor belts or robotic arms can be used to capture and transfer the fish to a designated harvesting area. This eliminates the need for manual handling and reduces stress on the fish.

Similarly, automated harvesting techniques can be employed for plants. Depending on the type of plants being grown, systems such as movable racks, conveyor systems, or robotic arms can be used to harvest the plants efficiently. These systems ensure minimal damage to the plants and reduce the time and labor required for harvesting.

In addition to harvesting, automation can also aid in post-harvest processing. For example, automated systems can be used to clean and pack harvested fish or sort and package harvested plants, ensuring consistent quality and presentation.

By automating the harvesting and post-harvest processes, farmers can maximize their yield, minimize waste, and maintain high-quality produce, creating a more efficient and profitable aquaponic operation.

Integrating Sensors and IoT in Aquaponic Automation: A Futuristic Approach

As technology continues to advance, the integration of sensors and the Internet of Things (IoT) opens up new possibilities for automation in aquaponics. IoT refers to the network of interconnected devices that can communicate and share data over the internet.

Sensors play a critical role in IoT-enabled systems by continuously collecting data on various parameters and transmitting it to central servers or control panels. In aquaponics, IoT-enabled sensors can monitor water quality, nutrient levels, temperature, and other crucial parameters. This real-time data can then be