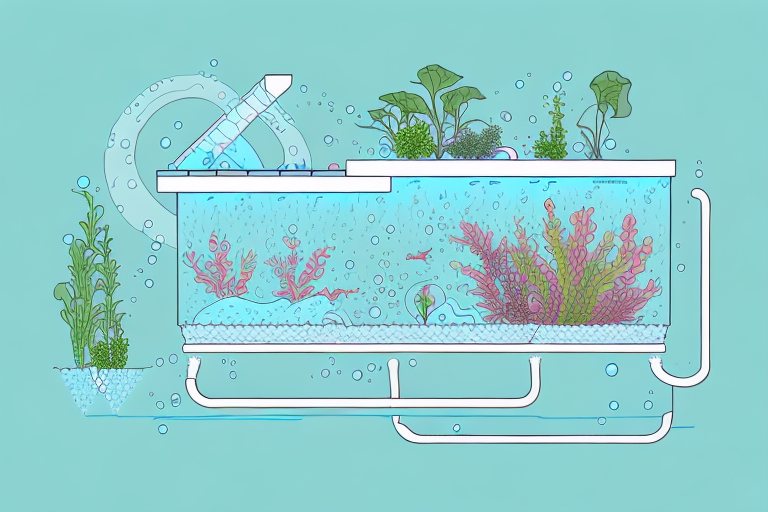

Aquaponics, a sustainable farming practice that combines aquaculture (fish farming) with hydroponics (growing plants in water), has gained significant popularity in recent years. As more farmers and garden enthusiasts discover the benefits of this innovative method, the need for automation in aquaponics systems becomes increasingly evident. Automation plays a crucial role in ensuring the quality and productivity of aquaponics operations, allowing for more efficient monitoring, nutrient delivery, water filtration, and overall control of the system. In this article, we will delve into the various aspects of automation in aquaponics, exploring its benefits, challenges, and future trends.

The Growing Popularity of Aquaponics Systems

In today’s world, where environmental sustainability is becoming a top priority, aquaponics offers an attractive alternative to traditional farming methods. The ability to create a closed-loop ecosystem that maximizes resources and minimizes waste is one of the main reasons for the growing popularity of aquaponics systems. By harnessing the symbiotic relationship between fish and plants, aquaponics allows for the production of both fresh, chemical-free vegetables and high-quality fish, all in a single integrated system. However, to optimize the potential of aquaponics and achieve consistent yields, automation is essential.

Understanding the Concept of Aquaponics

Aquaponics is built upon the principle of a mutualistic relationship between fish and plants. The fish produce waste in the form of ammonia, which is toxic to them, but acts as a nutrient source for plants. In turn, the plants filter the water, removing the harmful substances and returning clean water to the fish. This synergy creates a sustainable cycle, ensuring the survival and growth of both components. However, maintaining optimal conditions within an aquaponics system requires careful monitoring and fine-tuning, which can be accomplished through automation.

The Benefits of Automation in Aquaponics

Automation offers numerous benefits for aquaponics farmers, allowing them to achieve consistent production while reducing the amount of time and effort required to manage the system. One of the greatest advantages of automation is the ability to precisely monitor and control various parameters, such as water temperature, pH levels, dissolved oxygen, and nutrient concentrations. These factors play a critical role in the health and growth of both fish and plants. By utilizing automated monitoring systems, aquaponic farmers can ensure optimal conditions at all times, leading to improved productivity and increased crop yields.

Furthermore, automation enables farmers to conserve resources, such as water and energy, by using precisely targeted delivery systems. With automated feeding systems, for example, the exact amount of feed required by the fish can be dispensed, minimizing wastage and reducing the risk of water contamination. Similarly, automated filtration and aeration systems can optimize water quality and oxygenation, avoiding buildup of harmful substances and maintaining optimal conditions for both fish and plants.

Increasing Efficiency with Automated Monitoring Systems

Automated monitoring systems are integral to the success of aquaponics operations, as they provide real-time data and insights into the system’s performance. These systems utilize various sensors to measure and record parameters such as water temperature, pH levels, electrical conductivity, ammonia levels, and dissolved oxygen. By continuously monitoring these parameters, farmers can detect any deviations from the desired values and take immediate corrective actions to prevent potential issues.

Additionally, automated monitoring systems often come equipped with alert mechanisms, sending notifications to the farmer’s device if any parameter goes beyond predetermined thresholds. This proactive approach allows for timely intervention, preventing potential crises and ensuring the health and well-being of the fish and plants. With automation, aquaponics farmers can achieve higher levels of efficiency, reduce the risk of crop loss, and ultimately maximize the productivity of their systems.

The Role of Sensors and Controllers in Aquaponic Automation

Sensors and controllers are at the heart of automation in aquaponics. Sensors are responsible for collecting data on various environmental parameters, while controllers interpret this data and trigger appropriate actions to maintain optimal conditions. Sensors can include temperature sensors, pH sensors, conductivity sensors, dissolved oxygen sensors, and ammonia sensors, among others. These sensors continuously monitor the respective parameters, transmitting the data to the controllers for analysis.

Controllers, on the other hand, act as the brain of the automation system. They receive and process the sensor data, comparing it to predetermined setpoints or ranges. If any parameter deviates from the desired values, the controller triggers an appropriate action, such as activating a heating or cooling system, adjusting nutrient delivery, or activating aeration systems. By utilizing sensors and controllers, aquaponics farmers can create a highly efficient and self-regulating environment, ensuring optimal conditions for the growth of both fish and plants.

Optimizing Nutrient Delivery through Automated Feeding Systems

In aquaponics, nutrient delivery plays a pivotal role in the health and productivity of plants. Traditionally, feeding fish in aquaponics systems has been a manual process, requiring farmers to estimate the amount of feed needed. However, this approach can be imprecise and lead to overfeeding or underfeeding, resulting in suboptimal plant growth and potential water quality issues.

Automation simplifies and streamlines the feeding process by utilizing automated feeding systems. These systems can dispense feed at precise intervals and in predetermined quantities, based on factors such as fish biomass and growth rates. By delivering the right amount of feed at the right time, automated feeding systems optimize nutrient availability for the plants, preventing any nutrient deficiencies or excesses. This precision feeding not only leads to healthier plants but also reduces waste and improves overall system performance.

Maintaining Water Quality with Automated Filtration and Aeration

Water quality is crucial for the success of aquaponics systems, as it directly affects the health and well-being of both fish and plants. Maintaining optimal water quality involves filtration, oxygenation, and regular monitoring of key parameters. Automation plays a pivotal role in simplifying and optimizing these processes.

Automated filtration systems ensure that the water remains clean and free from any harmful substances or excess nutrients. By utilizing mechanical filters, such as foam filters or swirl separators, and biological filters, such as bio-media or bio-filters, these systems remove any solid waste or excess ammonia, creating a pristine environment for the fish and plants.

Similarly, automated aeration systems provide the necessary oxygen levels for both fish and plants. These systems often employ air pumps, diffusers, or venturis to oxygenate the water, ensuring a healthy and oxygen-rich environment. By automating filtration and aeration processes, aquaponics farmers can maintain water quality effortlessly, freeing up time and resources for other essential tasks.

Enhancing Plant Growth with Automated Lighting and Climate Control

Proper lighting and climate control are vital for the successful growth of plants in aquaponics systems. While natural sunlight is ideal, it may not always be available in sufficient quantities or at optimal intensities. In such cases, automated lighting systems can ensure that the plants receive the required amount of light for photosynthesis, growth, and development.

Automated lighting systems can be programmed to simulate natural daylight cycles, providing plants with the appropriate amount of light during the growing season. By using energy-efficient LED lights, these systems can minimize energy consumption while delivering the specific light wavelengths needed for optimal plant growth.

In addition to lighting, climate control is also critical in maintaining ideal growing conditions. Automated climate control systems can regulate temperature, humidity, and ventilation, ensuring that plants thrive in an environment that promotes growth and minimizes stress. By automating lighting and climate control, aquaponics farmers can enhance plant growth and achieve consistent yields throughout the year.

Streamlining Harvesting and Packaging Processes through Automation

Automation not only benefits the production phase of aquaponics systems but also simplifies and streamlines the harvesting and packaging processes. Traditional manual harvesting and packaging methods can be time-consuming and labor-intensive, potentially leading to delays or compromised product quality.

Automation offers solutions for efficient and precise harvesting and packaging. Automated harvesting systems can be designed to harvest plants at the optimal stage of growth, ensuring maximum freshness and nutritional value. These systems can be equipped with conveyor belts, robotic arms, or specialized tools to pick and package the produce accurately.

By automating these processes, aquaponics farmers can significantly reduce labor requirements and improve overall efficiency. This allows for quicker turnaround times, ensuring that the produce reaches consumers in the freshest possible condition.

Ensuring Food Safety and Quality Control through Automation

Food safety and quality control are paramount in any farming operation, including aquaponics systems. Automation plays a crucial role in ensuring compliance with food safety regulations and maintaining consistent product quality.

Automated monitoring systems, in conjunction with sensors and controllers, can continuously monitor critical parameters, such as water quality, temperature, and pH levels, to ensure they remain within acceptable ranges. If any parameter deviates from the desired values, automated systems can trigger alerts or corrective actions to rectify the issue promptly.

In addition to monitoring, automation can also facilitate traceability and record-keeping processes. Automated systems can accurately record and store data related to planting, harvesting, water quality, and nutrient delivery, allowing for easy retrieval and analysis. This data-driven approach enables aquaponics farmers to demonstrate compliance with food safety standards and implement corrective measures when necessary.

Case Studies: Successful Implementation of Automation in Aquaponics Farms

Across the world, numerous aquaponics farms have successfully implemented automation into their operations, reaping the benefits of increased productivity and efficiency.

One notable case is the 423-acre Green Sense Farms in Chicago, which boasts one of the largest automated indoor vertical aquaponics facilities in the world. By utilizing a combination of automated monitoring and control systems, Green Sense Farms consistently produces high-quality vegetables, with yields up to 26 times greater than traditional farming methods. The automation systems employed at Green Sense Farms have streamlined operations, reduced labor requirements, and facilitated precise nutrient delivery, resulting in optimal plant growth and minimized resource usage.

Overcoming Challenges in Automating Aquaponics Systems

While automation offers immense potential for aquaponics systems, it also comes with its share of challenges. One of the primary obstacles is the initial investment required to implement automation technology. The cost of sensors, controllers, monitoring systems, and other automation equipment can be substantial, particularly for small-scale farmers.

Additionally, the integration of different automation components can be complex and require technical expertise. Farmers may face challenges in selecting suitable automation solutions for their specific system, as compatibility and ease of use are important factors to consider.

Maintaining automation systems and troubleshooting potential issues can also be daunting for farmers. Training and support from automation providers and industry experts are crucial to overcome these challenges and ensure successful implementation and operation of automation in aquaponics systems.

Future Trends and Innovations in Aquaponic Automation Technology

The field of aquaponic automation is constantly evolving, with new technologies and innovations on the horizon.

One promising trend is the integration of artificial intelligence (AI) and machine learning algorithms into aquaponic automation systems. AI can analyze vast amounts of data collected from sensors and controllers, identifying patterns and optimizing system performance. Machine learning algorithms can continuously learn from the data, improving decision-making and allowing for predictive maintenance and optimized resource allocation.

Another area of future innovation is the use of remote monitoring through Internet of Things (IoT) connectivity. IoT-enabled sensors and devices can transmit data to cloud platforms, enabling farmers to monitor and control their aquaponics systems from anywhere, at any time. This remote accessibility provides farmers with enhanced flexibility, allowing them to respond to system issues promptly and make informed decisions based on real-time data.

Making Informed Decisions: Choosing the Right Automation Solutions for Your Aquaponic System

As automation becomes increasingly prevalent in the aquaponics industry, it is crucial for farmers to make informed decisions when selecting automation solutions for their systems.

First and foremost, farmers must assess their specific needs and objectives. Factors such as system size, crop types, available resources, and budget should be considered when choosing automation components. It is essential to select systems and equipment that are compatible with existing infrastructure and can be seamlessly integrated into the aquaponics system.

For farmers new to aquaponics or automation, seeking guidance from experts or consulting with established aquaponics operators can provide valuable insights. Learning from the experiences of others can help farmers avoid common pitfalls and make informed decisions that align with their goals.

Furthermore, thorough research and evaluation of automation providers will be instrumental in selecting trusted partners. Considering factors such as reputation, customer support, warranties, and scalability will help farmers choose reliable automation solutions that meet their long-term needs.

Conclusion

Automation in aquaponics is no longer a luxury; it has become a necessity to ensure the quality and productivity of aquaponics systems. By harnessing the power of automation, farmers can create efficient and self-regulating ecosystems that optimize resource utilization, maximize yields, and minimize waste. From monitoring and nutrient delivery to filtration and climate control, automation streamlines critical processes, allowing farmers to achieve consistent growth and maintain optimal conditions. With the ongoing advancements in automation technology and the increasing availability of solutions tailored to aquaponics, the future looks promising for those involved in this sustainable and innovative method of food production.

Now that you’ve reached the end of this article, we hope that you have gained a comprehensive understanding of the importance of automation in aquaponics. By embracing this technology, aquaponics farmers can enhance their operations, contribute to sustainable agriculture, and meet the ever-growing demand for high-quality, locally grown produce.