Aquaponics, the symbiotic combination of aquaculture and hydroponics, has gained immense popularity in recent years as a sustainable method of food production. By utilizing the natural relationship between fish and plants, aquaponics systems have the potential to produce large quantities of fresh produce and fish in a relatively small space. However, the cost of setting up and maintaining aquaponic systems can be a barrier for many aspiring farmers.

Introduction to Aquaponics and its Potential for Cost Reduction

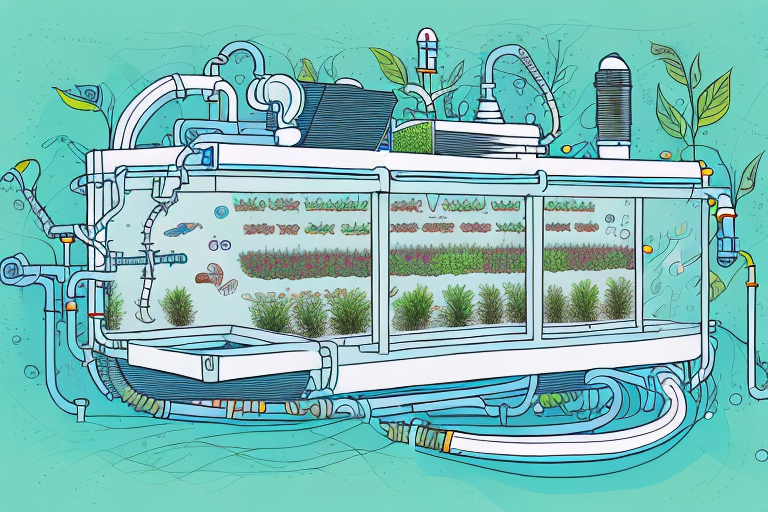

Aquaponics is a highly efficient method of food production that combines the growth of fish and plants in a closed-loop system. In this system, fish waste provides the necessary nutrients for plant growth, while the plants act as a natural filter, purifying the water for the fish. The result is a sustainable and productive ecosystem that requires little external inputs.

One of the main benefits of aquaponics is the potential for cost reduction compared to traditional farming methods. By harnessing the power of industrial techniques and automation, aquaponics systems can maximize efficiency and minimize operational costs.

Furthermore, aquaponics eliminates the need for chemical fertilizers and pesticides, reducing the costs associated with purchasing and applying these inputs. The closed-loop system also minimizes water usage, as water is continuously recycled within the system, reducing the need for large amounts of water typically required in traditional farming.

Benefits of Industrial Techniques and Automation in Aquaponics

Industrial techniques and automation play a vital role in achieving cost reduction in aquaponics. These techniques allow for the scaling up of operations, increasing production yield and reducing labor costs. Automation, on the other hand, streamlines processes and eliminates human error, resulting in improved efficiency.

By adopting industrial techniques such as vertical farming, multi-tiered cultivation, and optimized space utilization, aquaponic farms can significantly increase their production capacity. These techniques enable farmers to maximize the use of available space and grow crops vertically, allowing for higher yields per square foot.

In addition to cost reduction and increased production capacity, industrial techniques and automation in aquaponics also contribute to environmental sustainability. By implementing efficient water management systems, such as recirculating aquaculture systems, aquaponic farms can minimize water usage and reduce the environmental impact of traditional farming methods.

Furthermore, industrial techniques and automation in aquaponics can enhance food safety and quality. With automated monitoring and control systems, farmers can closely monitor water quality parameters, such as pH levels and dissolved oxygen, ensuring optimal conditions for both fish and plant growth. This results in healthier and safer produce for consumers.

Efficiency Improvements in Aquaponic Systems through Industrial Techniques

Industrial techniques also offer efficiency improvements in aquaponic systems. By integrating advanced technologies such as sensors, monitoring systems, and remote control mechanisms, farmers can effectively manage water and nutrient levels, ensuring optimal growing conditions for plants and fish.

Furthermore, the use of advanced filtration systems and water treatment technologies helps maintain the quality of water, reducing the risk of disease outbreaks and the need for frequent water changes. This leads to significant cost savings in terms of water usage and maintenance.

In addition to advanced technologies, industrial techniques in aquaponic systems also involve the use of automated feeding systems. These systems can accurately dispense the right amount of feed to the fish, ensuring they receive the necessary nutrients without overfeeding. This not only improves the overall health and growth of the fish but also reduces wastage and feed costs.

Moreover, industrial techniques in aquaponics often incorporate energy-efficient practices. This includes the use of energy-saving LED lights for plant growth, as well as the implementation of renewable energy sources such as solar panels to power the system. By reducing energy consumption and reliance on non-renewable resources, these techniques contribute to a more sustainable and environmentally friendly approach to aquaponics.

Optimizing Costs in Aquaponics through Automation and Technology

Automation and technology play a crucial role in optimizing costs in aquaponics. By automating tasks such as feeding, water circulation, and temperature control, farmers can reduce labor costs and improve overall system efficiency. Automated feeding systems, for example, ensure that fish are fed in precise quantities and at regular intervals, eliminating overfeeding and wastage of feed.

Similarly, automated water circulation systems help maintain proper flow and oxygenation in the system, ensuring the well-being of both fish and plants. Temperature control systems, powered by advanced sensors and controllers, enable farmers to create the optimal climate for growth while minimizing energy consumption.

In addition to automating feeding, water circulation, and temperature control, aquaponics systems can also benefit from the use of advanced monitoring and control systems. These systems allow farmers to remotely monitor and adjust various parameters such as pH levels, nutrient levels, and dissolved oxygen levels. By having real-time data and control over these parameters, farmers can optimize the growth conditions for both fish and plants, leading to higher yields and reduced costs.

Furthermore, the integration of technology in aquaponics can also include the use of data analytics and predictive modeling. By analyzing historical data and using predictive algorithms, farmers can make informed decisions regarding stocking densities, feed quantities, and crop rotation schedules. This data-driven approach helps optimize resource allocation, minimize waste, and maximize profitability in aquaponics operations.

Industrial-Scale Aquaponics: A Cost-Effective Approach to Sustainable Farming

Industrial-scale aquaponics offers a cost-effective approach to sustainable farming. By scaling up operations through optimized facility design, advanced machinery, and efficient use of resources, farmers can significantly reduce production costs per unit.

In industrial-scale aquaponics, economies of scale come into play, leading to lower costs of production. Large-scale operations benefit from bulk purchasing of inputs, reduced labor costs due to increased automation, and greater potential for wholesale marketing and distribution.

The Role of Automation in Reducing Operating Costs in Aquaponics

Automation plays a pivotal role in reducing operating costs in aquaponics. By automating labor-intensive tasks such as planting, harvesting, and seedling propagation, farmers can reduce their reliance on manual labor and streamline their operations.

Additionally, automation allows for precise control of environmental factors such as light, temperature, and humidity, enabling farmers to create optimal growing conditions for plants. This level of precision leads to higher crop yields and lower input costs.

Industrial Techniques for Improving Productivity and Reducing Costs in Aquaponics

There are several industrial techniques that can improve productivity and reduce costs in aquaponics. One such technique is the use of advanced lighting systems, including LED grow lights, which provide optimal light spectrum for plant growth while minimizing energy consumption.

Another technique is the use of automated nutrient dosing systems, which accurately deliver the required nutrients to plants, eliminating the need for manual mixing and reducing nutrient wastage. Furthermore, the implementation of advanced monitoring systems allows farmers to detect issues early on and take corrective measures, preventing crop loss and minimizing costs.

Key Components of an Automated Aquaponic System for Cost Reduction

An automated aquaponic system comprises several key components that contribute to cost reduction. These include:

– Sensor-based monitoring systems that track water parameters such as pH, temperature, and dissolved oxygen levels. This allows for efficient resource management and early detection of potential issues.

– Automated feeding systems that dispense the right amount of feed at the right time, reducing waste and optimizing fish growth.

– Remote control mechanisms that enable farmers to monitor and control their aquaponic systems from anywhere, minimizing the need for physical presence and reducing labor costs.

– Advanced filtration and water treatment systems that ensure water quality, reducing the risk of disease outbreaks and the need for frequent water changes.

Case Studies: Successful Implementation of Industrial Techniques and Automation in Aquaponics

Several case studies demonstrate the successful implementation of industrial techniques and automation in aquaponics. One such case study is the integration of robotic systems in a commercial aquaponic farm in Kentucky, USA. The robots perform tasks such as transplanting seedlings, harvesting mature plants, and monitoring water quality, leading to increased efficiency and reduced labor costs.

Another case study showcases the implementation of vertical farming in a large-scale aquaponic facility in the Netherlands. This technique allows for the cultivation of plants in vertically stacked layers, maximizing the use of available space and significantly increasing crop yields.

Cost Analysis: Comparing Traditional vs. Industrialized Aquaponic Systems

A cost analysis comparing traditional aquaponic systems to industrialized ones reveals significant cost savings. Traditional systems often require manual labor for tasks such as feeding, planting, and harvesting, resulting in higher labor costs. In contrast, industrialized systems that utilize automation and advanced technology can reduce labor requirements and improve productivity, leading to cost savings.

Furthermore, industrialized systems benefit from the efficient use of resources, such as water and nutrients, and the ability to control environmental factors, resulting in higher crop yields and reduced input costs.

Technological Innovations Driving Cost Reduction in Aquaponics

Technological innovations play a crucial role in driving cost reduction in aquaponics. Advancements in sensor technology, automation systems, and data analysis tools have revolutionized the industry, allowing for more efficient resource management and improved decision-making.

For example, the development of advanced water quality monitoring sensors enables real-time tracking of parameters such as pH, temperature, and nutrient levels, ensuring optimal conditions for plant and fish growth. This precision monitoring leads to reduced input costs and higher productivity.

Overcoming Challenges: Implementing Automation and Industrial Techniques in Aquaponic Farms

Implementing automation and industrial techniques in aquaponic farms can pose certain challenges. One of the main challenges is the initial investment required for the setup and installation of automation systems and advanced machinery. However, it is important to consider the long-term benefits and cost savings that automation can bring.

Another challenge lies in the integration of different components and technologies. It is crucial to ensure compatibility and proper configuration of automation systems, sensors, and control mechanisms to maximize efficiency and avoid costly errors.

Future Trends: Advancements in Industrial Techniques and Automation for Cost Reduction in Aquaponics

The future of aquaponics is promising, with ongoing advancements in industrial techniques and automation. Emerging trends include the development of intelligent systems that utilize artificial intelligence and machine learning algorithms to optimize resource management and predict plant growth patterns.

Moreover, the integration of renewable energy sources such as solar power and geothermal energy can further reduce operating costs and increase sustainability in aquaponic systems.

Best Practices for Integrating Industrial Techniques and Automation into Aquaponic Operations

To successfully integrate industrial techniques and automation into aquaponic operations, it is essential to follow best practices. These include:

– Conducting thorough feasibility studies to assess the potential benefits and costs of implementing automation and industrial techniques.

– Engaging with industry experts and seeking advice from experienced aquaponic farmers who have successfully implemented automation.

– Gradual implementation and testing of automation systems to ensure smooth integration and minimize disruption to existing operations.

– Regular monitoring and maintenance of automation systems to ensure proper functioning and minimize downtime.

Conclusion

In conclusion, cost reduction in aquaponics can be achieved through the adoption of industrial techniques and automation. By leveraging advanced technologies and streamlined processes, aquaponic farms can increase productivity, reduce labor costs, and optimize resource utilization. The integration of industrial-scale operations and automation allows for economies of scale, leading to significant cost savings. With continued advancements in technology and ongoing research, the future of aquaponics looks promising in terms of cost reduction and sustainable food production.