Industrial aquaponics is revolutionizing the aquaculture industry, providing a sustainable and efficient solution for food production. This integrated system combines aquaculture, the farming of fish and other aquatic animals, with hydroponics, the cultivation of plants in water, to create a symbiotic relationship where each element benefits the other. In this article, we will explore the intricacies of industrial aquaponics, its advantages and benefits, and its potential for widespread adoption.

What is Industrial Aquaponics and How Does it Work?

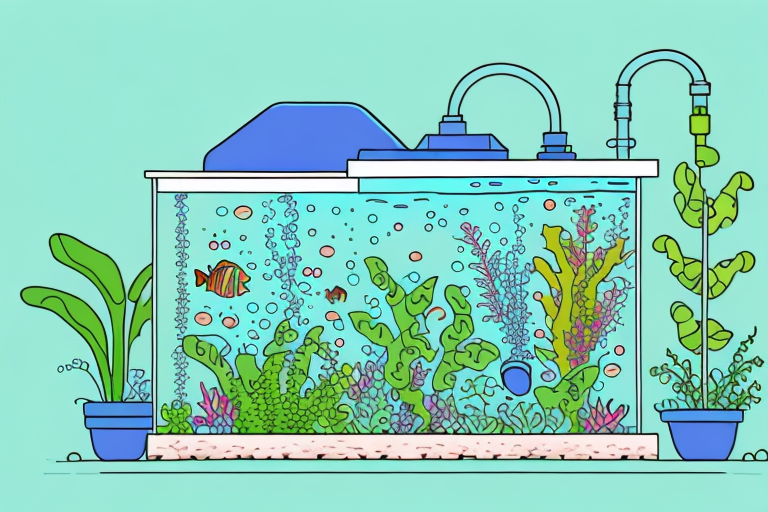

At its core, industrial aquaponics is a method of farming that utilizes the waste produced by fish as a nutrient-rich fertilizer for plants, while the plants in turn filter and purify the water for the fish. The system consists of a fish tank or tanks where the aquatic animals are cultivated, and a series of grow beds or rafts where the plants are grown. The fish waste, which contains ammonia, is broken down by naturally occurring bacteria and converted into nitrates, a form of nitrogen that plants can readily absorb. As the water flows from the fish tank to the grow beds, the plants take up the nitrates, purifying the water and returning it back to the fish tank.

This closed-loop system eliminates the need for external fertilizers, pesticides, and herbicides, making industrial aquaponics a highly sustainable and organic method of farming. By simulating a natural ecosystem, this innovative approach minimizes water usage and significantly reduces the environmental impact typically associated with traditional aquaculture and agriculture practices.

One of the key advantages of industrial aquaponics is its ability to produce a wide variety of crops. The nutrient-rich water in the system allows for the cultivation of not only leafy greens and herbs but also fruits, vegetables, and even flowers. This versatility makes industrial aquaponics an attractive option for farmers looking to diversify their produce and meet the demands of a diverse market.

The Rise of Industrial Aquaponics: Advantages and Benefits

The advantages and benefits of industrial aquaponics are multifaceted, making it an attractive option for the aquaculture industry. Firstly, the integration of fish and plant cultivation maximizes resource utilization and space efficiency. Compared to traditional farming methods, aquaponics systems can produce a greater amount of food in a smaller footprint, making it ideal for urban and land-constrained areas.

Furthermore, industrial aquaponics reduces the risk of disease outbreaks and pests. The natural filtration process in the system helps maintain optimal water quality, minimizing the need for chemicals and antibiotics commonly used in conventional aquaculture practices. This not only ensures the health and well-being of the fish but also provides consumers with safer and healthier food options.

Additionally, industrial aquaponics offers economic opportunities for job creation and revenue generation. The sector requires a skilled workforce to operate and manage the systems, providing employment opportunities in both urban and rural communities. Moreover, the production of high-value crops, such as leafy greens and herbs, alongside fish farming can lead to increased profitability for farmers.

Moreover, industrial aquaponics has a positive environmental impact. The closed-loop system significantly reduces water usage compared to traditional farming methods. The water in the aquaponics system is continuously recycled, minimizing the need for excessive irrigation and reducing the strain on freshwater resources. Additionally, the integration of plants helps to remove excess nutrients from the water, preventing water pollution and eutrophication.

A Sustainable Solution: How Industrial Aquaponics Reduces Environmental Impact

One of the most significant advantages of industrial aquaponics is its reduced environmental impact. Traditional aquaculture often results in the discharge of nutrient-rich wastewater into natural water bodies, contributing to water pollution and eutrophication. In contrast, industrial aquaponics recirculates and reuses water, resulting in significant water conservation. The closed-loop system minimizes water requirements, making it a more sustainable option for food production, particularly in water-scarce regions.

Furthermore, industrial aquaponics eliminates the need for chemical fertilizers and pesticides that often find their way into the environment. By relying on natural processes and beneficial bacteria to break down and convert waste, this system promotes organic farming practices, reducing the overall ecological footprint.

Additionally, the integration of plants in industrial aquaponics acts as a phytoremediation system, removing pollutants and excess nutrients from the water. This assists in preventing the build-up of harmful substances and maintaining water quality for the fish. The dual benefits of reduced water pollution and improved ecosystem health make industrial aquaponics a sustainable and environmentally friendly alternative to conventional aquaculture.

Moreover, industrial aquaponics has the potential to reduce greenhouse gas emissions compared to traditional aquaculture. The closed-loop system minimizes the release of nitrogen and phosphorus compounds into the atmosphere, which are major contributors to climate change. By efficiently utilizing nutrients and minimizing waste, industrial aquaponics helps mitigate the environmental impact associated with food production.

In addition to its environmental benefits, industrial aquaponics also offers economic advantages. The integration of fish and plant production in a single system allows for increased productivity and profitability. Farmers can generate income from both fish and plant sales, diversifying their revenue streams. Furthermore, the reduced reliance on external inputs, such as fertilizers and pesticides, can lead to cost savings for farmers. This makes industrial aquaponics an attractive option for sustainable and economically viable food production.

Maximizing Efficiency: The Role of Technology in Industrial Aquaponics

Technological advancements play a crucial role in maximizing the efficiency of industrial aquaponics systems. Monitoring and automation systems help farmers maintain optimal conditions for both fish and plants, ensuring their health and growth. These systems utilize sensors, actuators, and control algorithms to regulate water temperature, pH levels, and nutrient concentrations, minimizing human error and maintaining a stable environment.

Furthermore, the integration of renewable energy sources, such as solar panels and wind turbines, can power the system, reducing reliance on conventional energy sources. This not only contributes to the sustainability of industrial aquaponics but also lowers operational costs for farmers.

Technology also enables data collection and analysis, allowing farmers to monitor and optimize their production processes. By capturing real-time data on water quality, fish behavior, and plant growth, farmers can make informed decisions to improve operational efficiency and productivity. Advanced analytics can also be used to predict and prevent potential issues, ensuring the smooth functioning of the system.

In addition to monitoring and automation systems, technology in industrial aquaponics also includes the use of remote sensing devices. These devices can be installed throughout the aquaponics system to collect data on various parameters such as water flow, dissolved oxygen levels, and nutrient concentrations. This real-time data can be transmitted wirelessly to a central control system, allowing farmers to remotely monitor and adjust the system as needed.

Another technological advancement in industrial aquaponics is the development of specialized software applications. These applications are designed to assist farmers in managing their operations more efficiently. They can provide features such as inventory management, crop planning, and financial analysis. By utilizing these software applications, farmers can streamline their processes, reduce waste, and make data-driven decisions to optimize their aquaponics production.