Aquaponics, a sustainable farming method that combines aquaculture (fish farming) with hydroponics (soilless plant cultivation), has gained increasing attention in recent years. As the world faces challenges such as climate change, population growth, and food security, innovative approaches like aquaponics offer promising solutions. In this article, we will explore the future of aquaponics, focusing on the pivotal role of automation and industrialization in transforming this farming method.

Introduction to Aquaponics: A Sustainable Farming Method

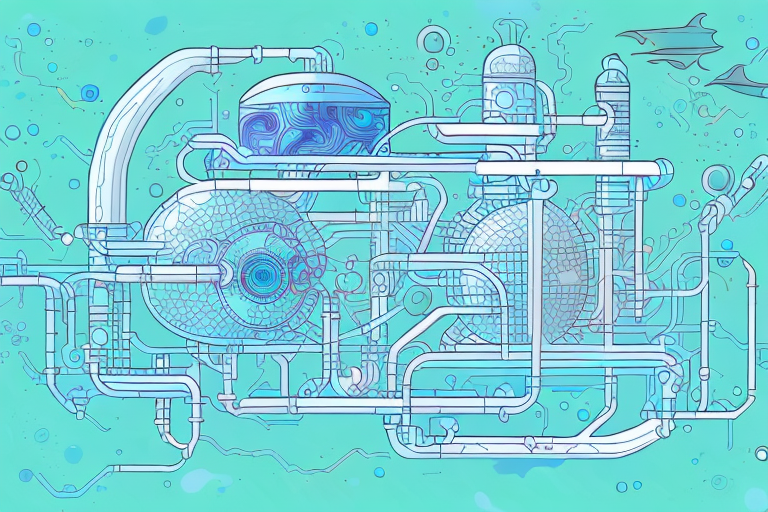

At its core, aquaponics is a symbiotic system that relies on the natural interactions between fish, plants, and beneficial bacteria. The fish excrete waste, which contains nutrients that are then converted into forms that can be readily absorbed by plants. In turn, the plants filter and purify the water, creating a healthy environment for fish. This closed-loop system minimizes water usage and eliminates the need for synthetic fertilizers, pesticides, and herbicides, making aquaponics an eco-friendly and highly sustainable farming method.

One of the key advantages of aquaponics is its ability to produce a high yield of crops in a small space. Because the plants are grown vertically in towers or troughs, rather than horizontally in traditional soil beds, aquaponic systems can maximize the use of limited space. This makes aquaponics particularly suitable for urban farming or areas with limited land availability.

In addition to its space-saving benefits, aquaponics also offers a significant reduction in water usage compared to conventional farming methods. The closed-loop system in aquaponics recirculates water, minimizing the need for constant irrigation. The water is continuously filtered and purified by the plants, ensuring that it remains clean and free from harmful substances. This efficient use of water not only conserves this precious resource but also reduces the risk of water pollution from agricultural runoff.

The Rise of Automation in Aquaponics Systems

With the advancement of technology, automation has found its way into aquaponics systems, revolutionizing the way they are operated. Automated systems can monitor and control crucial parameters such as water temperature, pH levels, nutrient concentrations, and oxygen levels, ensuring optimal conditions for both fish and plants.

By automating tasks that were previously carried out manually, such as feeding fish, adjusting water levels, and monitoring water quality, aquaponics farmers can streamline their operations, reduce labor costs, and ultimately increase productivity. Additionally, automation improves the precision and consistency of operations, leading to more predictable yields and higher overall efficiency.

Benefits of Automation in Aquaponics: Efficiency and Productivity

The benefits of automation in aquaponics are manifold. Firstly, it allows farmers to devote more time to critical decision-making and strategic planning, as routine tasks are handled by automated systems. This frees up valuable human resources and enables farmers to focus on maximizing the productivity and profitability of their operations.

Furthermore, automation enhances the control and fine-tuning of environmental conditions, optimizing plant growth and fish health. By maintaining stable and optimal parameters, automation minimizes stress on the system, reducing the risk of disease outbreaks and crop failures. This, in turn, improves the overall efficiency and yields of aquaponics farms.

How Industrialization is Transforming Aquaponics Farms

Industrialization plays a pivotal role in taking aquaponics to the next level. As farms scale up and strive for commercial viability, the adoption of industrial-grade equipment and practices becomes crucial. Industrialized aquaponics farms are characterized by large-scale production, increased automation, and the integration of advanced technologies.

Industrial-grade aquaponics systems facilitate higher fish stocking densities and greater plant cultivation areas. This scalability enables farmers to meet the demands of larger markets and creates opportunities for economies of scale, further driving down production costs.

Technology and Innovation in Aquaponics: Advancements and Trends

As the aquaponics industry continues to grow, technological advancements and innovative solutions are emerging. These include the integration of artificial intelligence (AI), robotics, and the Internet of Things (IoT) into aquaponics systems.

For instance, AI algorithms can analyze data from various sensors and make informed decisions regarding water quality adjustments and fish feeding regimes. This automation enhances system performance and reduces the chances of human error. Similarly, robotics can handle tasks such as planting, harvesting, and transplanting, reducing the need for manual labor and optimizing efficiency.

The IoT, through real-time monitoring and control, enables farmers to remotely manage their aquaponics systems. This connectivity and accessibility empower farmers to monitor key parameters, receive alerts, and adjust system settings from anywhere, enhancing convenience and efficiency.

The Role of Artificial Intelligence in Automating Aquaponics Processes

Artificial intelligence has the potential to revolutionize aquaponics by leveraging machine learning algorithms to optimize processes. AI-driven systems can learn from data collected in real-time and provide actionable insights to farmers, facilitating informed decision-making.

For example, AI algorithms can analyze historical data on water quality, environmental conditions, and crop growth patterns to predict future trends. This predictive capability enables farmers to anticipate challenges and adjust operations accordingly, leading to increased yields and resource efficiency.

Enhancing Crop Yields with Automated Nutrient Monitoring and Delivery Systems

One of the key challenges in aquaponics is achieving the optimal balance of nutrients for plant growth. Automated nutrient monitoring and delivery systems can effectively address this challenge.

Sensors placed within the system can continuously measure nutrient levels, ensuring that plants have access to an adequate supply. Automated dosing mechanisms then adjust nutrient concentrations by adding precise amounts of fertilizers or by manipulating the fish feed composition. This real-time monitoring and adjustment capability enables farmers to achieve maximum crop yields and maintain plant health.

Streamlining Operations with Robotics in Aquaponics Farms

Robotics is increasingly being integrated into aquaponics farms to improve efficiency and reduce labor requirements. Robots can not only handle repetitive tasks such as planting and harvesting but can also perform more complex actions, such as monitoring plant health and detecting anomalies.

For instance, aerial drones equipped with sensors can fly over plant beds, capturing data on crop health and growth rates. This data can then be analyzed to identify areas that require attention, such as nutrient deficiencies or disease outbreaks, allowing farmers to take targeted corrective measures.

IoT Integration in Aquaponics: Real-Time Monitoring and Control

The Internet of Things (IoT) offers immense potential for aquaponics by enabling real-time monitoring and control of essential parameters. IoT devices, such as sensors and actuators, can be strategically placed throughout the system to capture and transmit data wirelessly.

These devices continuously monitor key parameters, including temperature, pH levels, dissolved oxygen, and nutrient concentrations, providing data insights to farmers. By leveraging IoT technology, farmers can remotely observe the state of their aquaponics systems, make timely adjustments, and receive alerts in case of any deviation from the desired conditions.

Analyzing Data for Improved Decision-Making in Automated Aquaponics Systems

Automated aquaponics systems generate vast amounts of data that can be harnessed for improved decision-making. By analyzing this data, farmers can gain valuable insights into the performance of their systems, identify trends, and make data-driven modifications.

Data analysis can be used to optimize various aspects of aquaponics operations, including fish feeding schedules, water quality management, and plant growth patterns. By leveraging data analytics, farmers can fine-tune their systems, resulting in improved efficiency, increased yields, and ultimately, sustainable profitability.

Challenges and Considerations for Scaling up Industrialized Aquaponics Operations

While the prospect of industrialized aquaponics holds great promise, there are challenges that must be addressed to ensure successful scaling up of operations. One such challenge is the high capital costs associated with the adoption of industrial-grade equipment and technologies. Farms intending to scale up need to carefully evaluate and plan their investments to ensure long-term profitability.

Additionally, there is a need for suitable regulatory frameworks and standards for industrialized aquaponics operations. This ensures that farms adhere to best practices and maintain high-quality produce while minimizing any negative environmental impacts associated with large-scale aquaponics systems.

Sustainability at Scale: Balancing Automation with Environmental Impact

As aquaponics farms industrialize and embrace automation, maintaining sustainability remains a key priority. While automation brings numerous benefits, it is crucial to strike a balance between increased productivity and minimizing environmental impacts.

Farmers must prioritize responsible water usage, energy-efficient technologies, and ecological sustainability. Implementing practices such as water recycling, renewable energy utilization, and minimizing waste can ensure that aquaponics continues to be a sustainable farming method, even at large scales.

Economic Impacts of Industrialized Aquaponics on Local Communities

The industrialization of aquaponics holds significant economic potential for local communities and regions. Large-scale aquaponics operations can create employment opportunities, ranging from system design, installation, and maintenance to marketing and sales.

Furthermore, industrialized aquaponics farms can supply fresh, locally grown produce to nearby markets, reducing the need for long-distance transportation and cutting down carbon emissions. This enhances food security, stimulates local economies, and promotes community resilience.

Empowering Local Food Production through Automated Aquaponics Systems

Aquaponics, particularly when combined with automation, has the potential to empower local food production. By establishing aquaponics systems in urban areas, food production can be brought closer to consumers, reducing dependence on large-scale, centralized agricultural systems.

Automated aquaponics systems can be implemented in limited space environments, such as rooftops, vertical farms, or abandoned warehouses, enabling urban dwellers to have access to fresh and nutritious produce year-round. This localized food production helps build more resilient and sustainable communities.

Potential Barriers to Adoption of Industrialized Aquaponics Methods

While industrialized aquaponics holds much promise, there are several barriers that hinder its widespread adoption. One of the foremost challenges is the lack of awareness and understanding of aquaponics among the general public and potential investors.

Education, outreach, and community engagement are essential to foster knowledge and appreciation for aquaponics, dispel any misconceptions, and garner support for its expansion. Collaborations between industry stakeholders, research institutions, and governments can play a vital role in promoting information sharing and driving the adoption of industrialized aquaponics methods.

Harnessing the Power of Big Data in Optimizing Automated Aquaponic Systems

Big data analytics has the potential to revolutionize how automated aquaponic systems are managed. By capturing and analyzing vast amounts of data generated by sensors, cameras, and other monitoring devices, farmers can gain valuable insights and optimize their operations.

Data analytics can provide real-time information on key system parameters, identify trends, and detect anomalies. This enables farmers to adjust their operations promptly, fine-tune their systems for maximum efficiency, and prevent or mitigate potential issues. The integration of big data analytics in aquaponics holds the promise of unlocking further potential for increased productivity and sustainability.

Future Prospects: Towards Fully Autonomous and Integrated Aquaponic Farms

The future of aquaponics holds immense potential for fully autonomous and integrated farms. As technology continues to advance, we can envision a future where aquaponics systems are seamlessly connected, operated, and managed by intelligent algorithms and AI systems.

Fully automated and integrated aquaponic farms could leverage advanced sensors to continuously monitor and optimize every aspect of the system in real-time. This includes adjusting environmental conditions, predicting and preventing diseases, and optimizing nutrient delivery. The result would be highly efficient, self-sustaining ecosystems that produce food with minimal human intervention.

In conclusion, the future of aquaponics is undeniably intertwined with automation and industrialization. These advancements bring benefits such as increased efficiency, scalability, and economic viability. However, they also require careful attention to sustainability, environmental impact, and social equity. By leveraging emerging technologies and practices, aquaponics has the potential to revolutionize the agricultural landscape, providing a sustainable and reliable source of food for generations to come.