Aquaponics, a sustainable farming system that combines aquaculture and hydroponics, is gaining widespread popularity due to its ecological and economic benefits. In recent years, the advent of Industrial Internet of Things (IoT) technology has revolutionized various industries, including agriculture. The integration of IoT in aquaponics has opened up new possibilities for automation, improved efficiency, and enhanced productivity. This article aims to provide a comprehensive overview of the role of Industrial IoT in aquaponics automation, exploring its benefits, applications, challenges, and future prospects.

Introduction to Aquaponics: A Sustainable Farming System

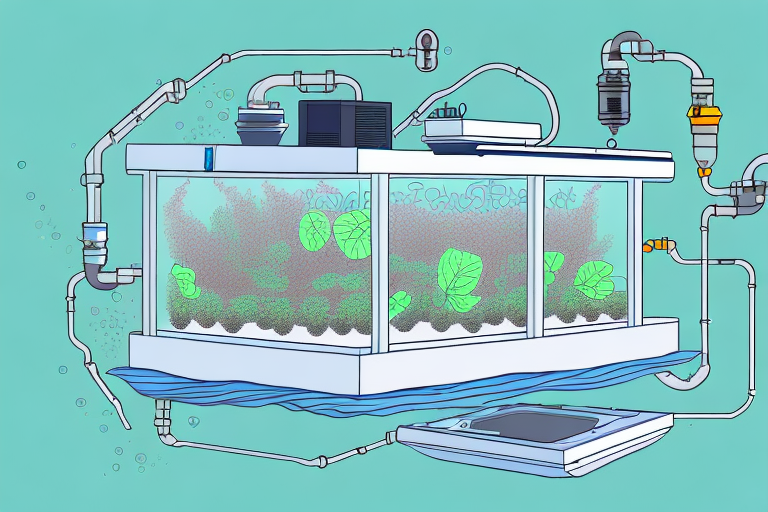

Aquaponics is a closed-loop system that combines fish farming (aquaculture) and plant cultivation (hydroponics). It operates on the symbiotic relationship between fish and plants, where nutrient-rich fish waste serves as fertilizer for plant cultivation, while the plants filter and purify the water for the fish. This sustainable farming system minimizes water usage, eliminates the need for synthetic fertilizers, and produces both fish and crops simultaneously.

In recent years, aquaponics has gained attention as a sustainable alternative to traditional farming methods. Its ability to produce more food with fewer resources and its potential for year-round cultivation make it an attractive solution for food security, especially in urban areas with limited space for conventional farming.

Understanding Industrial IoT: Revolutionizing Agriculture

Industrial IoT refers to the integration of digital technologies and smart devices within industrial processes, enabling real-time data collection, analysis, and automated decision-making. This transformative technology has significantly impacted various sectors, improving efficiency, reducing costs, and enhancing productivity.

In agriculture, Industrial IoT has emerged as a game-changer, transforming traditional farming practices into smart and automated systems. By connecting sensors, devices, and machinery, IoT enables real-time monitoring, data analysis, and automation in agricultural processes. Industrial IoT is now being applied to aquaponics to optimize the entire farming system and revolutionize food production.

Harnessing the Power of IoT in Aquaponics Automation

The integration of Industrial IoT in aquaponics brings numerous benefits, particularly in terms of automation and data-driven decision-making. IoT sensors can be placed in aquaponics systems to monitor key parameters such as water temperature, pH levels, dissolved oxygen, and nutrient concentrations.

These sensors continuously collect data and transmit it to a central hub or cloud-based platform, where it can be analyzed in real-time. Automated systems can then adjust parameters such as water flow, nutrient delivery, and lighting based on the analyzed data, optimizing the conditions for maximum crop growth and fish health.

By automating tasks that were previously time-consuming and labor-intensive, Industrial IoT enables aquaponics farmers to focus on higher-level activities such as crop planning, market analysis, and system optimization, ultimately improving productivity and profitability.

Improving Efficiency and Productivity in Aquaponics through Industrial IoT

The incorporation of Industrial IoT in aquaponics systems significantly improves efficiency and productivity. Real-time data collected by IoT sensors provides farmers with valuable insights into the performance of their farming systems. By analyzing this data, farmers can identify trends, patterns, and anomalies that may impact crop growth, fish health, and overall system performance.

With this knowledge, farmers can make informed decisions to optimize their aquaponics systems. For example, they can adjust nutrient delivery based on plant nutrient requirements or implement preventive measures to avoid disease outbreaks. By fine-tuning the system based on data-driven insights, farmers can achieve higher crop yields and ensure the well-being of their fish.

Moreover, IoT technology enables remote monitoring and control of aquaponics systems, eliminating the need for farmers to be physically present at all times. This flexibility allows farmers to manage multiple farms simultaneously, increasing their productivity and expanding their operations.

Smart Sensors and Monitoring Systems for Aquaponics Automation

At the heart of Industrial IoT in aquaponics automation are smart sensors and monitoring systems. These sensors are designed to measure and monitor various environmental parameters critical for the well-being of fish and plants. Examples of such sensors include temperature sensors, pH sensors, dissolved oxygen sensors, electrical conductivity sensors, and ammonia sensors.

By placing these sensors strategically in different parts of the aquaponics system, farmers can collect accurate and real-time data on the conditions affecting their crops and fish. This data is essential for making informed decisions and taking timely actions to ensure optimal growth conditions.

In addition to environmental sensors, IoT technology enables the integration of other smart devices such as smart pumps, automated feeders, and lighting systems. These devices can be programmed to operate based on predefined parameters, further automating the aquaponics system.

Real-time Data Analysis and Decision Making in Aquaponics with IoT

Real-time data analysis plays a crucial role in leveraging the power of Industrial IoT in aquaponics automation. The continuous collection of data from sensors generates a vast amount of information that can be analyzed for optimizing system performance.

Data analysis in aquaponics involves identifying patterns, correlations, and trends that provide insights into the system’s behavior and performance. Machine learning algorithms can be applied to the collected data to make predictions, detect anomalies, and optimize system parameters automatically.

By analyzing real-time data, farmers can make more informed decisions regarding water quality management, nutrient delivery, and overall system control. This data-driven approach enables a proactive approach to aquaponics farming, minimizing risks and maximizing output.

Enhancing Crop Yield and Quality with Industrial IoT in Aquaponics

Industrial IoT in aquaponics has the potential to significantly enhance crop yield and quality. The precise control and monitoring of environmental parameters, such as water temperature, pH levels, and nutrient concentrations, enable optimal growing conditions for plants.

Through this fine-tuned control, Industrial IoT facilitates increased growth rates, accelerated maturity, and improved crop quality. By continuously monitoring and adjusting key parameters, farmers can create optimal conditions that result in healthier plants, higher yields, and better marketable produce.

Furthermore, the integration of IoT in aquaponics also allows for the cultivation of a wide range of vegetables, herbs, and even specialty crops that require precise environmental control. The ability to tailor growing conditions to specific crops expands the opportunities for aquaponics farmers, enabling diversification and higher profitability.

Water Quality Management and Control in Aquaponics using Industrial IoT

Water quality management is critical in aquaponics, as it directly affects both fish health and plant growth. Industrial IoT technology provides real-time monitoring and control of water quality parameters, ensuring optimal conditions for the entire aquaponics system.

IoT sensors continuously measure parameters such as temperature, dissolved oxygen, pH levels, and electrical conductivity to gauge water quality. If any deviation is detected, IoT systems can trigger automated actions, such as adjusting pH levels or increasing aeration, to maintain optimal conditions without human intervention.

By continuously monitoring and adjusting water quality parameters, Industrial IoT technology minimizes the risk of stress-related issues for fish and ensures that plants receive the necessary nutrients for healthy growth. This precise control leads to improved fish health and higher crop yields.

Optimizing Nutrient Delivery and Fish Health Monitoring with IoT in Aquaponics

The well-being of fish in aquaponics systems is essential for the overall success of the farming venture. Industrial IoT technology enables real-time monitoring of fish health parameters, including water quality, temperature, and behavior patterns.

IoT sensors placed in fish tanks collect data on key health indicators and transmit it to the central system for analysis. If any anomalies are detected, such as abnormal behavior or stress indicators, the system can automatically adjust parameters or notify the farmer for appropriate action.

Moreover, IoT technology allows for precise control and optimization of nutrient delivery to plants. By continuously monitoring nutrient levels and plant requirements, farmers can fine-tune nutrient delivery systems to ensure optimal growth conditions. This targeted approach to nutrient delivery reduces waste, maximizes plant uptake, and promotes efficient resource utilization.

Cost Reduction and Resource Optimization through Industrial IoT in Aquaponics

One of the significant advantages of Industrial IoT in aquaponics is its potential for cost reduction and resource optimization. By automating and optimizing various aspects of aquaponics farming, IoT technology can significantly reduce labor costs, time, and resource wastage.

Automated control systems can regulate water flow, nutrient levels, and lighting based on real-time data, thereby ensuring resource efficiency and minimizing waste. Additionally, remote monitoring and control enable farmers to manage multiple aquaponics systems without the need for physical presence on-site, further reducing labor costs.

Furthermore, Industrial IoT facilitates predictive maintenance by continuously monitoring equipment performance and detecting potential faults or malfunctions. By addressing maintenance needs proactively, farmers can prevent costly breakdowns, optimize system uptime, and extend the lifespan of their equipment.

Case Studies: Successful Implementation of Industrial IoT in Aquaponics Farms

Several aquaponics farms around the world have successfully implemented Industrial IoT technology, showcasing its benefits and potential. For instance, a commercial aquaponics farm in the Netherlands has integrated IoT sensors to monitor water quality, climate, and plant growth. This real-time data analysis system has enabled the farm to optimize growth conditions, reduce water and energy consumption, and significantly increase crop yields.

In Australia, an aquaponics farm has leveraged IoT technology to automate fish feeding, monitor water quality, and collect environmental data. The use of IoT sensors and automated control systems has not only improved fish growth rates but also enhanced crop quality, resulting in increased profitability.

These case studies highlight the successful implementation of Industrial IoT in aquaponics, providing inspiration and insights for other farmers and investors looking to adopt this innovative technology.

Future Prospects: Advancements and Innovations in Industrial IoT for Aquaponics Automation

Industrial IoT is a rapidly evolving field, and its potential for aquaponics automation is vast. As technology continues to advance, we can expect exciting innovations that further optimize aquaponics systems and revolutionize the future of sustainable agriculture.

One significant area of development is the integration of artificial intelligence (AI) and machine learning (ML) algorithms with IoT technology. By employing AI and ML, aquaponics systems can learn from historical data, optimize system parameters, and make predictive recommendations for improved performance.

Additionally, advancements in sensor technology and connectivity solutions will enable more precise and comprehensive data collection. Sensors that can detect a wider range of parameters or smaller variations in environmental conditions will enhance system control and provide even more accurate insights.

Moreover, the integration of blockchain technology with Industrial IoT in aquaponics has the potential to enhance traceability and transparency in the food supply chain. By recording and verifying every stage of production, certification, and distribution on a distributed ledger, blockchain technology can ensure food safety, eliminate fraud, and build trust among consumers.

Challenges and Considerations for Implementing Industrial IoT in Aquaponics Systems

While Industrial IoT offers significant advantages for aquaponics automation, its implementation comes with certain challenges and considerations that need to be addressed for successful adoption.

One of the primary challenges is the initial investment required for setting up an IoT-enabled aquaponics system. The installation of smart sensors, data management platforms, automation equipment, and connectivity solutions may involve substantial upfront costs. However, it is essential to consider the long-term benefits and potential return on investment that IoT can bring to aquaponics operations.

Another consideration is data security and privacy. With the integration of IoT and cloud-based platforms, sensitive data is being transmitted and stored, raising concerns about unauthorized access and data breaches. Implementing robust data encryption protocols and ensuring compliance with data protection regulations can help alleviate these concerns.

Furthermore, the complex nature of IoT systems and the need for technical expertise present a challenge for farmers looking to adopt this technology. Proper training and support from IoT providers or consultants are crucial to ensure successful implementation and utilization of IoT-enabled aquaponics systems.

Sustainable Farming Practices: How Industrial IoT is Contributing to a Greener Future

Aquaponics, coupled with Industrial IoT, represents a significant step towards achieving sustainable and environmentally friendly farming practices. By minimizing water consumption, eliminating the use of synthetic chemicals, and reducing waste, aquaponics already contributes to a greener, more sustainable agriculture sector.

However, by harnessing the power of IoT technology, aquaponics systems can achieve even greater efficiency, productivity, and resource optimization. The ability to automate and control critical parameters such as water quality, nutrient delivery, and lighting enables farmers to fine-tune their systems and reduce waste to an unprecedented level.

Industrial IoT also enables precision farming, where resources are used only when and where necessary, minimizing environmental impact and maximizing yields. This approach aligns with the objectives of sustainable agriculture, promoting responsible resource management, biodiversity conservation, and climate change mitigation.

In conclusion, Industrial IoT holds immense potential in revolutionizing aquaponics automation. Through the integration of smart sensors, data analysis, and automation, IoT technology enables optimized growth conditions, enhanced productivity, and improved system performance. The real-time monitoring and control provided by Industrial IoT in aquaponics contribute to cost reduction, resource optimization, and ultimately, a greener future for sustainable farming practices.